8 Important Skills Required for Mechanical Engineering

Mar 18, 2025 5 Min Read 36544 Views

(Last Updated)

When someone says Mechanical engineering, the first thing that comes to all of our minds is either automobiles or mechanics. We think that’s what mechanical engineering is all about and deem it to be an easy one. But in truth, it is not. The skills required for mechanical engineering are diverse and one cannot learn it just by watching automobile-related movies or shows.

Mechanical engineering is one of the crucial subjects that is the foundation of every other field. Be it the equipment used in an industry to the medical devices that save a lot of lives to machines of the construction industry, everything comes down to mechanical engineering.

To understand the skills required for mechanical engineering, we formulated this article that can give you a great insight. So, without further ado, let’s get started.

Table of contents

- What is Mechanical Engineering?

- Skills Required for Mechanical Engineering

- Strong Mathematical and Analytical Skills

- Problem-Solving Abilities

- Proficiency in Physics and Mechanics

- Technical Drawing and Computer-Aided Design (CAD)

- Materials Knowledge

- Thermodynamics and Fluid Dynamics

- Knowledge of Manufacturing Processes

- Programming Skills

- Conclusion

- FAQ

- What skills are required to become a successful mechanical engineer?

- Why is proficiency in physics and mechanics essential for mechanical engineers?

- What manufacturing processes should a mechanical engineer be familiar with?

- How does proficiency in technical drawing benefit a mechanical engineer's career?

What is Mechanical Engineering?

Once upon a time, the department that was famous among most Indians especially boys was mechanical engineering. It had so much craze that in every other college-based movie, the protagonist would always seem pursuing mechanical engineering. Before we go with the skills required for mechanical engineering, let us understand what mechanical engineering is all about.

Mechanical engineering is a branch of engineering that focuses on the design, analysis, development, and maintenance of mechanical systems and devices. It encompasses a wide range of activities related to the creation of physical objects and systems that involve moving parts, energy transfer, and the application of mechanical principles.

Mechanical engineers use their knowledge of physics, mathematics, materials science, and other engineering disciplines to design and create various mechanical systems and devices. These can include everything from simple components to complex machines.

Now you know, why I said that mechanical engineering is not an easy subject. It involves every subject and requires intricate knowledge of it.

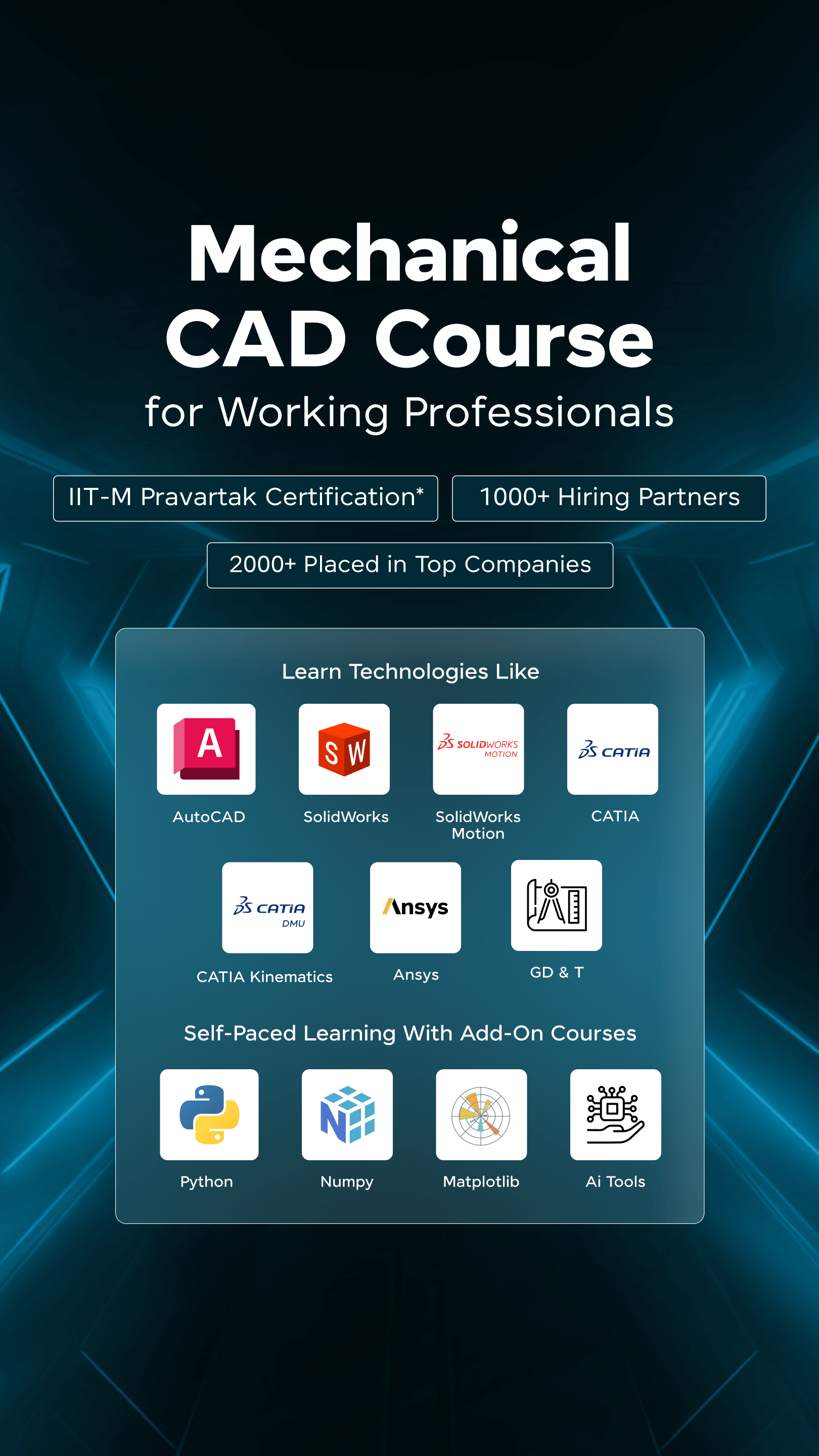

Before we move on to the next part, you should have a deeper knowledge of key mechanical engineering concepts. You can consider enrolling yourself in GUVI’s CAD Program for Mechanical Engineers, which lets you gain practical experience by developing real-world projects and covers technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc.

Additionally, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

Skills Required for Mechanical Engineering

We curated a list of the 8 important skills required for mechanical engineering and these are the common ones found in every other mechanical engineering job description. Let us not waste any more time and we’ll start right away:

1. Strong Mathematical and Analytical Skills

The only regret part of taking up mechanical engineering is that it involves a lot of mathematics and if you are someone who hates maths, please understand that mathematics has a huge role to play in the field of mechanical engineering. Keep that in mind before opting to pursue this one.

Strong mathematical and analytical skills are required for mechanical engineering to decipher complex problems, quantify physical phenomena, and formulate precise solutions.

These skills enable engineers to model intricate systems, predict behavior under varying conditions, and optimize designs, ensuring that mechanical components and systems are structurally sound, efficient, and perform as intended.

Mathematical proficiency allows engineers to translate real-world challenges into quantifiable terms, facilitating the creation of innovative solutions that meet technical requirements and elevate the field of mechanical engineering.

2. Problem-Solving Abilities

Mechanical engineering is all about building solutions for real-time real-world problems. In order to do so, mechanical engineering must possess the most sought-after ability which is problem-solving.

Problem-solving abilities are crucial for a mechanical engineer as they allow professionals to divide intricate challenges, identify underlying issues, and devise effective strategies to come up with a solution.

By applying analytical thinking and systematic approaches, engineers can unravel complex scenarios, formulate hypotheses, and test solutions. This skill not only ensures the creation of innovative designs but also enables engineers to troubleshoot and rectify issues during the manufacturing, operation, or maintenance phases.

Problem-solving proficiency lies at the core of a mechanical engineer’s toolkit, enabling them to navigate uncertainties and contribute to advancements in diverse industries through their creative problem-solving prowess.

3. Proficiency in Physics and Mechanics

Another subject that is interesting yet complex and plays a huge role in mechanical engineering is Physics. As we have read in our school, without physics, no advancement can happen and that is true for mechanical engineering too. Physics and Mechanics are two important skills required for mechanical engineering.

Proficiency in physics and mechanics is essential for a mechanical engineer as it provides the foundational understanding of how objects interact with forces, motion, and energy.

This expertise enables engineers to predict the behavior of mechanical systems, analyze stress and strain distributions in materials, and design components that withstand operational conditions.

By mastering the principles of physics and mechanics, engineers can optimize designs for efficiency, safety, and durability, ensuring that the final products and systems function reliably and effectively within the constraints of real-world applications.

4. Technical Drawing and Computer-Aided Design (CAD)

Till now we have seen the theoretical skills required for mechanical engineering but this one is different. A creative skill that involves the design process is computer-aided design.

Technical drawing and computer-aided design (CAD) are integral skills required for mechanical engineering, facilitating the translation of conceptual ideas into precise visual representations and detailed models.

Technical drawings, traditionally executed on paper or digitally, enable engineers to communicate design specifications, dimensions, and tolerances with clarity to manufacturers, colleagues, and stakeholders. These drawings provide a universal language that ensures accurate fabrication and assembly of components, allowing seamless collaboration across multidisciplinary teams.

Furthermore, CAD software has revolutionized mechanical engineering by offering advanced tools for creating 2D drawings and 3D models. Engineers use CAD to generate intricate designs, simulate real-world behavior, and assess the feasibility of their concepts before physical production.

Proficiency in CAD empowers mechanical engineers to visualize, refine, and iterate designs with precision, resulting in optimized solutions that align with functional requirements and industry standards. It is recommended to take up an online certified course on CAD to understand the concepts much better.

5. Materials Knowledge

No matter how much knowledge you gain regarding the subject, it won’t matter unless you know about the basics which is the materials knowledge.

Materials knowledge is a fundamental aspect of a mechanical engineer’s skill set, encompassing an understanding of different materials’ properties, behaviors, and applications.

This expertise enables engineers to select appropriate materials for specific design requirements, considering factors such as strength, durability, thermal conductivity, and corrosion resistance.

Moreover, materials knowledge extends beyond selection, it also encompasses the ability to innovate and create new materials that cater to specific engineering challenges.

Engineers with a deep grasp of materials science can develop novel alloys, composites, and coatings that push the boundaries of what’s achievable in terms of mechanical performance, weight reduction, and energy efficiency.

6. Thermodynamics and Fluid Dynamics

The whole world has now shifted its focus towards sustainability and energy-efficient methods. This involves the understanding of heat transfer modes, fluid properties, and so on. The combined knowledge of these is what we call thermodynamics and fluid dynamics which are considered to be important skills required for mechanical engineering.

Thermodynamics explores the principles governing energy conversion and transfer, enabling engineers to design efficient engines, power generation systems, and heat exchangers.

It provides insights into maximizing energy utilization, understanding the efficiency limits of processes, and optimizing thermal systems for minimal waste and optimal performance.

Moreover, thermodynamics plays a crucial role in developing sustainable energy solutions, as engineers work on renewable energy systems and innovative technologies that address the global energy challenge.

In parallel, fluid dynamics focuses on understanding the motion and behavior of fluids—both liquids and gases—within mechanical systems.

Engineers who are experts in the field of fluid dynamics can analyze fluid flow patterns, predict pressure distributions, and optimize designs to minimize resistance and maximize efficiency. A

Applications range from designing aircraft aerodynamics and automotive cooling systems to refining pipelines and understanding ocean currents.

Fluid dynamics is instrumental in addressing challenges related to turbulence, boundary layers, and fluid-structure interactions, enabling mechanical engineers to develop safe, efficient, and environmentally conscious designs across industries.

7. Knowledge of Manufacturing Processes

One of the crucial roles of a mechanical engineer lies in the manufacturing process and it is important for everyone to understand the things that go behind the manufacturing process as these are the skills required for mechanical engineering to stand out from the crowd.

A comprehensive knowledge of manufacturing processes is a cornerstone of mechanical engineering, gaining familiarity with a diverse array of techniques used to transform raw materials into finished products.

This expertise enables engineers to make informed decisions about material selection, process optimization, and quality control throughout the manufacturing lifecycle. Engineers well-versed in manufacturing processes understand the intricacies of techniques such as machining, casting, forging, molding, additive manufacturing (3D printing), and welding.

Furthermore, a deep understanding of manufacturing processes extends beyond the theoretical to practical application. They collaborate effectively with production teams to troubleshoot issues, reduce waste, and improve efficiency on the factory floor. This knowledge empowers mechanical engineers to bridge the gap between design and production, ensuring that their innovative concepts materialize into functional and cost-effective products.

8. Programming Skills

Though mechanical engineering doesn’t require programming knowledge on the surface. But learning those skills can be really useful and keeps you on edge over others.

Proficiency in programming languages such as Python, MATLAB, and C++ allows engineers to create customized tools, scripts, and algorithms that streamline complex tasks. This capability extends to data analysis, where engineers can process large datasets to extract valuable insights and make informed design decisions.

MATLAB is one such language that has profound use cases. Almost every manufacturing industry is now employing this language as it proves to be handy and user-friendly. Learning this is an easy task and one can master it in no time.

Moreover, programming skills like Python enable the automation of repetitive processes, enhancing efficiency and accuracy in tasks like simulations, parametric design, and optimization. It is important to learn Python as that can take your resume one step up.

Conclusion

In conclusion, as the demand for mechanical engineers continues to evolve in response to global challenges, the skills required for mechanical engineering remain pivotal, and it is your duty to cultivate and master them as these skills can make your portfolio look professional.

The integration of these skills not only empowers you, as a mechanical engineer to design efficient, reliable, and innovative systems but also enables you to drive technological advancements that shape our modern world. That’s it regarding the skills required for a mechanical engineer and if you have any queries or doubts, feel free to put it down in the comment section below.

Kickstart your career by enrolling in GUVI’s CAD Career Program for Mechanical Engineers where you will master technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc, and build interesting real-life mechanical projects.

Alternatively, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

FAQ

Essential skills include strong mathematical and analytical abilities, problem-solving skills, proficiency in physics and mechanics, technical drawing and CAD skills, materials knowledge, and programming and computational skills.

Proficiency in physics and mechanics helps engineers understand how forces, motion, and energy interact, guiding the design and analysis of mechanical systems for optimal performance and safety.

Mechanical engineers should understand processes such as machining, casting, molding, and additive manufacturing, enabling them to choose appropriate techniques for efficient production.

Proficiency in technical drawing allows mechanical engineers to create accurate and detailed representations of designs, enhancing communication with colleagues and manufacturers and ensuring precise manufacturing.

nice & simple but efficient just 10 points to communicate the info nice work