How 3D Rendering is evolving Mechanical Product Design? Interesting Facts to Read!

Mar 07, 2025 4 Min Read 3188 Views

(Last Updated)

In the dynamic fields of product design and mechanical engineering, the integration of cutting-edge technologies has become the core to drive innovation and efficiency. 3D rendering stands out as a transformative force, reshaping the landscape of mechanical product design.

But what exactly is 3D rendering, and how does it play a role in enhancing the process of crafting mechanical wonders?

In this blog, we’ve discussed the ins and outs of the impact of 3D rendering in Mechanical product design. This might help you grasp the essence of the industry trends. Before we delve in, let us quickly find out what 3D rendering means in the world of mechanical product design.

Table of contents

- What is 3D Rendering?

- How 3D Rendering Is Improving Mechanical Product Design?

- Enhanced Insights

- Improved Communication

- Clear Experimentation

- Faster Prototyping

- Reduced Costs

- Realistic Simulation

- Improved Collaboration and Feedback

- Comprehensive Documentation

- Streamlined Productivity

- The Future of 3D Rendering in Mechanical Product Design

- Real-Time Rendering for Instant Feedback

- Immersive Virtual Reality Experiences

- AI-Driven Rendering for Predictive Design

- Cloud-Based Rendering

- Wrapping Up

- Frequently Asked Questions

- What is 3D Modelling in mechanical engineering?

- Which 3D software is best for mechanical engineering?

- What is mechanical CAD design?

- What is the salary package of a mechanical design engineer in India?

What is 3D Rendering?

In the context of mechanical product design, 3D Rendering is the act of transforming blueprints and schematics into real-world and visually stunning representations. This process is crucial in providing a tangible preview of the final product, aiding in decision-making, and facilitating effective communication among stakeholders.

One of the key benefits of 3D rendering in mechanical product design lies in its ability to visualize complex concepts and design ideas. Traditional 2D drawings can’t convey the design completely, leading to misinterpretations. With 3D rendering, designers can create real-life simulations, allowing all stakeholders to get insights into the nuances of the product before it even hits the production unit. This precision plays a vital role in minimizing errors and optimizing the design process.

Also, 3D rendering bridges the gap between designers, engineers, and clients. Presenting a tangible visual representation, facilitates smoother interactions, enabling stakeholders to provide feedback and make more informed decisions. This collaborative synergy not only accelerates the design phase but also ensures that the end product aligns seamlessly with the envisioned specifications.

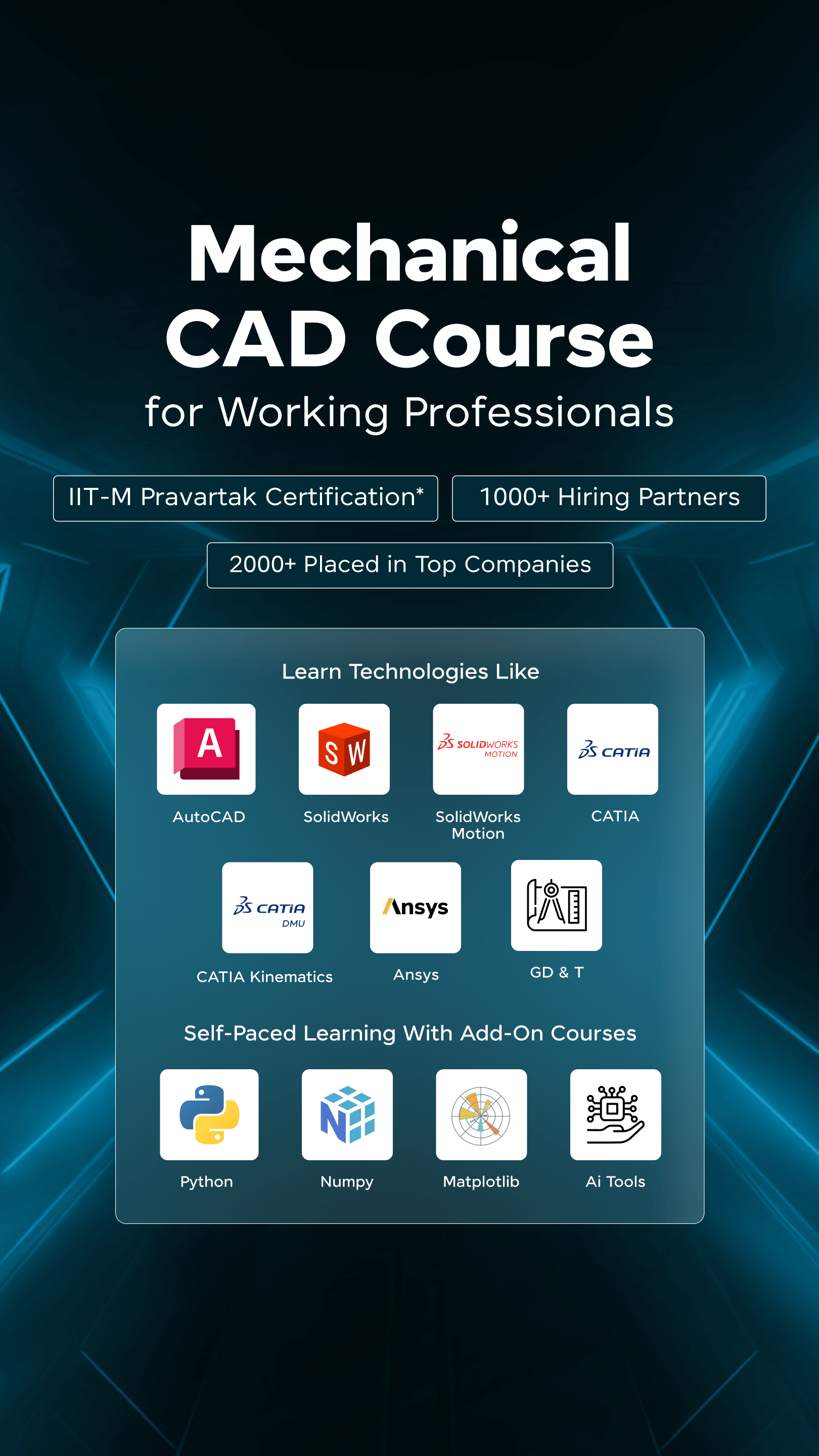

Before we move on to the next part, you should have a deeper knowledge of key mechanical engineering concepts. You can consider enrolling yourself in GUVI’s CAD Program for Mechanical Engineers, which lets you gain practical experience by developing real-world projects and covers technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc.

Additionally, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

Explore Generating Concepts for Product Design: Step-by-Step Guide [2024]

How 3D Rendering Is Improving Mechanical Product Design?

3D rendering plays a crucial role in mechanical product design, offering various benefits that contribute to the overall efficiency, accuracy, and success of the design process. Here are some of the key advantages:

Enhanced Insights

3D rendering provides a realistic visualization of the mechanical product, allowing designers, engineers, and stakeholders to better understand the appearance and functionality of the final product.

Improved Communication

With the feedback from 3D Rendering, Complex design concepts can be effectively communicated to team members, clients, and other stakeholders, reducing the chances of misinterpretation and ensuring everyone is on the same page.

Clear Experimentation

3D Rendering allows for thorough experimentation during the process of product design. This enables us to examine the look and feel of the mechanical product, including textures, colors, lighting, shapes, sizes, etc without having to develop separate prototypes.

Also Read 9 Impressive Real-world Applications of Mechanical Engineering

Faster Prototyping

3D rendering facilitates rapid prototyping by allowing designers to visualize and test multiple design iterations quickly and efficiently.

Reduced Costs

3D renders have the visual capabilities and metadata to detect and remove many problems efficiently. They allow engineers to optimize and detect issues before the final production begins. Identifying design flaws early in the process helps in avoiding costly errors and modifications during the later stages of product development.

Realistic Simulation

3D rendering enables realistic simulations of mechanical product behavior under various conditions. This helps in evaluating performance, stress analysis, and other critical factors without the need for physical prototypes. Designers can optimize the product for performance, durability, and other parameters based on simulation results, leading to more robust and efficient designs.

Improved Collaboration and Feedback

3D rendering facilitates effortless collaboration. Multiple team members can work on the same virtual model simultaneously, regardless of their geographical locations. Designers can easily incorporate feedback from various stakeholders, ensuring that the final product meets the requirements and expectations of all stakeholders.

Comprehensive Documentation

3D rendering allows for the creation of comprehensive design documentation, including detailed visual representations and annotations. High-quality renders enhance the quality of presentations, whether for internal reviews with stakeholders, client meetings, or investor pitches.

Streamlined Productivity

3D rendering contributes to this efficiency by optimizing manufacturing processes, streamlining production workflows, minimizing waste, and ensuring that each component aligns seamlessly with the overall design. This not only enhances productivity but also contributes to sustainable and cost-effective manufacturing practices.

Also read | Generative Design: Navigating the Future of Mechanical Engineering

The Future of 3D Rendering in Mechanical Product Design

The advancements in 3D Rendering are revolutionizing the way we conceive, develop, and manufacture products in real-time. Let’s explore the exciting possibilities that the future of 3D Rendering holds for Mechanical products.

Real-Time Rendering for Instant Feedback

The next frontier in 3D rendering technology for mechanical product design is real-time rendering. Real-time rendering has the potential to transform the traditional linear design cycle into an agile and dynamic process, fostering exceptional creativity and efficiency. This capability not only accelerates the design iteration process but also empowers designers and engineers with immediate feedback.

Immersive Virtual Reality Experiences

As Virtual Reality continues to roar, the integration of immersive experiences into the mechanical product design workflow is on the rise. Designers and engineers will have the ability to interact with their creations in a virtual environment. This advancement opens new avenues for collaborative design sessions, where team members from around the world can interact in a shared virtual space.

AI-Driven Rendering for Predictive Design

Artificial Intelligence is making a significant debut in various industries, and 3D rendering is no exception. AI-driven rendering algorithms help designers with predictive design outcomes, and identification of potential issues, and they also suggest optimizations. This predictive capability streamlines the design process and motivates designers to explore innovative solutions.

Find Out 14 Best AI Image Generator Tools

Cloud-Based Rendering

In the future of 3D rendering technology, cloud-based rendering services will occupy new avenues and empower designers and engineers to collaborate seamlessly on global projects. The ability to access powerful rendering resources from anywhere in the world not only enhances collaboration but also democratizes access to advanced rendering capabilities without geographical restrictions.

Also Read: What is CAM (Computer-aided Manufacturing)?

Kickstart your career by enrolling in GUVI’s CAD Career Program for Mechanical Engineers where you will master technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc, and build interesting real-life mechanical projects.

Alternatively, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course.

Wrapping Up

The precision, collaboration, and efficiency offered by 3D rendering technology enhance the boundaries of the mechanical product design industry. As we navigate this exciting landscape of innovation, we can conclude that 3D rendering is a catalyst for future advancements in this field.

3D rendering offers a wide range of benefits, from improving visualization and communication to facilitating iterative design, reducing costs, and enhancing collaboration throughout the entire product development lifecycle. Also, from real-time rendering and immersive VR experiences to AI-driven predictive design and Cloud-Based Rendering, these advancements redefine the boundaries of creativity, innovation, and efficiency in mechanical product design.

How has 3D rendering impacted your approach to design? What challenges have you overcome, and what opportunities has it unlocked? Let us know your thoughts in the comments below.

Frequently Asked Questions

3D modeling in mechanical engineering is the creation of three-dimensional representations of objects or systems using specialized computer software. It allows engineers to digitally design and visualize complex components in mechanical product design.

3D software like SolidWorks, and AutoCAD are often considered some of the best choices for mechanical product design and engineering purposes.

Mechanical CAD Design is the efficient use of computer software to create digital models of mechanical parts, components, and systems. It is used by mechanical product designers in various industries for designing machinery, products, and mechanical systems.

The average salary of a Mechanical Product Design Engineer in India is INR 5 to 5.5 LPA.

Did you enjoy this article?