AutoCAD vs SolidWorks: Which Design Tool Is Right for You?

Jan 10, 2025 6 Min Read 1203 Views

(Last Updated)

SolidWorks is primarily a 3D parametric modelling tool, while AutoCAD excels as a 2D technical drawing powerhouse. Although both can dip into each other’s domains—SolidWorks can handle 2D, and AutoCAD can model in 3D—they truly shine in their respective areas of expertise.

When you think of SolidWorks, picture intricate 3D designs, mechanical parts, and detailed assemblies, all brought to life precisely. AutoCAD, on the other hand, is synonymous with clean, accurate 2D drafts for architecture, civil engineering, and more. Both tools are indispensable but serve different needs depending on the industry and project.

This blog ‘AutoCAD Vs Solidworks’ dives into these two CAD titans’ strengths, applications, and differences. Whether you’re an engineer, architect, or designer, we’ll help you understand which software fits your workflow and how each can elevate your designs.

Table of contents

- Historical Background and Evolution

- AutoCAD: Revolutionizing Drafting Since 1982

- SolidWorks: Making 3D CAD Accessible Since 1995

- Differences in Purposes and Features

- Purpose: What Each Tool is Designed For

- Features: What Sets Them Apart

- Difference in Application Areas

- AutoCAD Applications

- SolidWorks Applications

- Differences in User Interface and Ease of Use

- Differences in Pricing and Licensing

- AutoCAD Pricing

- SolidWorks Pricing

- Difference in Workflow Integration

- Benefits of Each Software

- Final Thoughts

- Frequently Asked Questions - AutoCAD Vs SolidWorks

- Is AutoCAD easier to learn than SolidWorks?

- Can AutoCAD be used for 3D modelling like SolidWorks?

- Which industries benefit the most from AutoCAD and SolidWorks?

Historical Background and Evolution

The histories of AutoCAD and SolidWorks are rich and distinct, showcasing how each became a cornerstone in the world of CAD software. Understanding their origins and evolution provides insight into their unique strengths and applications.

AutoCAD: Revolutionizing Drafting Since 1982

Introduced by Autodesk in 1982, AutoCAD was the first CAD software designed for personal computers. Before its arrival, CAD programs ran on expensive mainframe systems, limiting accessibility. AutoCAD democratized design by offering a more affordable solution that allowed users to create detailed 2D and basic 3D drawings on PCs.

Key milestones in AutoCAD’s evolution include:

- 1982: AutoCAD 1.0 launched with support for DWG files, setting a new standard for CAD software.

- 1986: Became the most widely used design tool globally, a position it still holds today.

- 2007: Introduction of annotative objects and 3D modelling enhancements.

- 2023: Advanced features like My Insights: Macro Advisor and improved Trace capabilities make AutoCAD a leader in design flexibility.

AutoCAD has continually adapted to industry demands, becoming indispensable in fields such as architecture, construction, and animation.

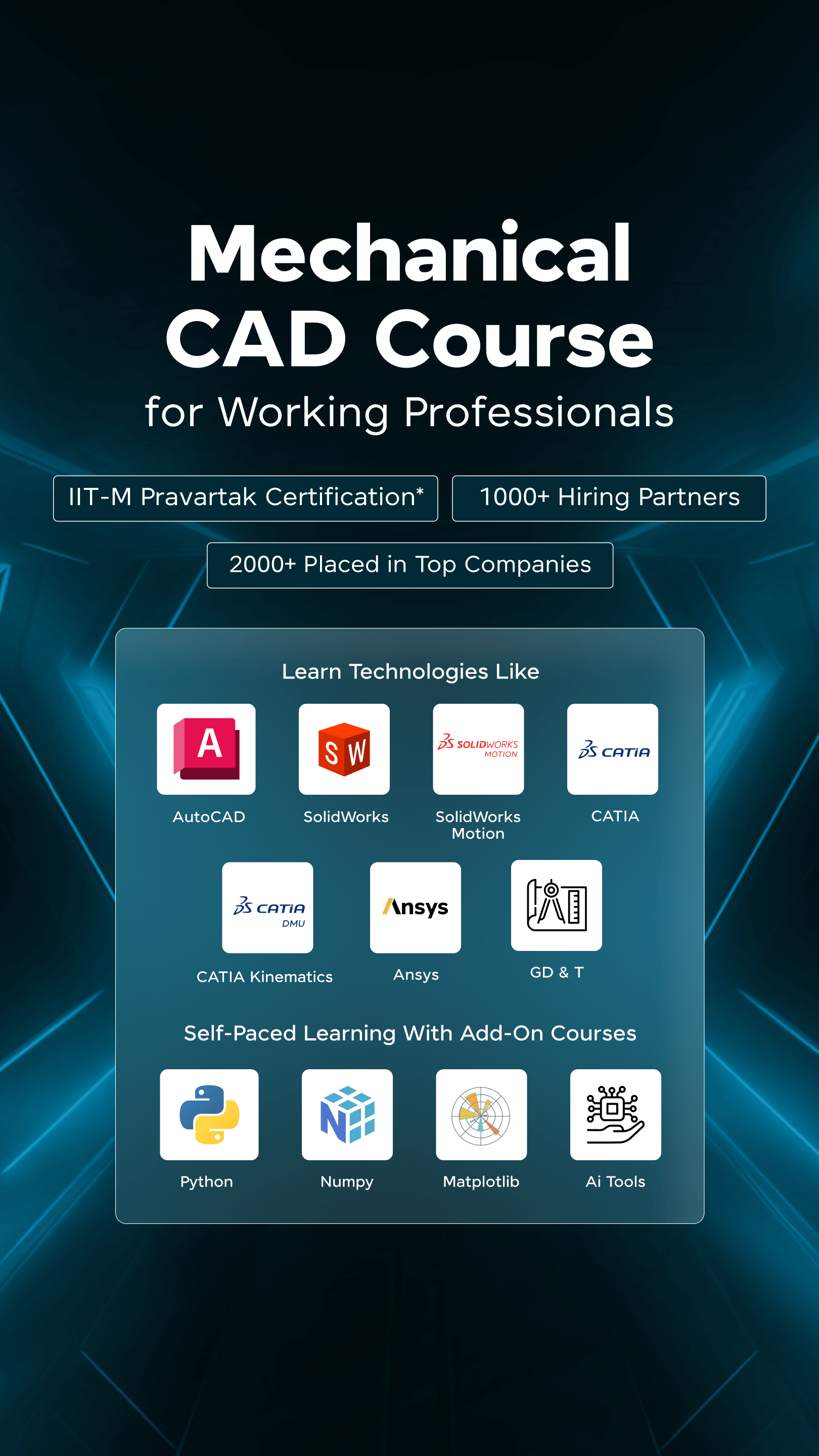

The IITM Pravartak and Autodesk Certified CAD Design and Simulation for Mechanical Engineers Course provides hands-on training for those seeking to specialise in mechanical design. This program equips learners with advanced CAD simulation skills to tackle real-world engineering challenges.

SolidWorks: Making 3D CAD Accessible Since 1995

SolidWorks debuted in 1995, spearheaded by Jon Hirschtick and his team with a vision to simplify 3D CAD on the Windows platform. Unlike its Unix-based competitors, SolidWorks offered a user-friendly interface and affordability, making it an instant hit.

Key milestones in SolidWorks’ evolution include:

- 1995: Launch at $4,000, far more accessible than competitors priced at $18,000.

- 1997: Acquired by Dassault Systèmes, enabling rapid advancements like in-context modelling.

- 2003: Introduction of COSMOSXpress, making simulation accessible to designers.

- 2023: Enhanced features for 3D performance, improved assembly functions, and new simulation tools solidify its place as a mechanical design leader.

SolidWorks transformed 3D design with parametric modelling and simulation, becoming a go-to tool for mechanical engineers and product designers.

Differences in Purposes and Features

When comparing AutoCAD and SolidWorks, their distinctions become clear in how they cater to specific design needs. Each tool has its strengths, tailored to its target audience and purpose.

Purpose: What Each Tool is Designed For

AutoCAD is the go-to tool for 2D drafting and general-purpose design. It’s widely recognized for its ability to create precise technical drawings, whether it’s an architectural blueprint, an engineering schematic, or a civil layout. While AutoCAD does have basic 3D capabilities, its strength lies in delivering accurate 2D designs that work across a variety of industries.

SolidWorks, on the other hand, is tailored for 3D parametric modelling and mechanical design. Its primary audience includes mechanical engineers and product designers who need to build detailed 3D models and test them under real-world conditions. From designing intricate machinery to assembling complex components, SolidWorks excels where 3D precision is critical.

Features: What Sets Them Apart

AutoCAD offers a robust set of 2D drafting tools, making it ideal for creating floor plans, infrastructure layouts, and technical illustrations. While it can handle basic 3D modelling, it’s better suited for users of 2D workflows. One of AutoCAD’s standout features is its exceptional file compatibility—it supports formats like DWG and DXF, ensuring easy sharing and collaboration across platforms.

SolidWorks, by contrast, is built for advanced 3D modelling and simulation. Its parametric design approach allows users to adjust dimensions and features without starting from scratch, maintaining design integrity. Additionally, its simulation tools—covering stress analysis, motion studies, and thermal performance—make it indispensable for mechanical engineers working on performance-critical designs. SolidWorks’ assembly features enable users to build and test multi-component systems for compatibility and efficiency.

Also Explore | CAD Designer Salary Insights: What to Expect and How to Unlock Your Earning Potential in India

Difference in Application Areas

AutoCAD and SolidWorks each carve out a unique niche in the design world, empowering professionals to excel in their specific domains. Their capabilities reflect the diverse needs of industries ranging from construction to mechanical engineering.

AutoCAD Applications

1. Architecture:

In architecture, AutoCAD serves as the trusted tool for creating detailed floor plans and construction blueprints. Its 2D and 3D visualization capabilities help architects not just draft designs but also present them with clarity, allowing clients to visualize spaces before a single brick is laid.

2. Civil Engineering:

AutoCAD’s precision shines in infrastructure projects. From site layouts to complex road and bridge plans, it equips civil engineers with tools to draft and document every crucial detail. Its accuracy ensures the smooth execution of projects that shape urban landscapes.

3. Electrical Engineering:

Designing electrical systems requires meticulous attention to detail, and AutoCAD delivers. It allows engineers to craft accurate circuit diagrams, wiring layouts, and schematics, ensuring systems work seamlessly from concept to installation.

4. Interior Design:

For interior designers, AutoCAD provides a digital canvas to map out furniture layouts, lighting designs, and space planning. Whether it’s a cosy home or a sprawling hotel, AutoCAD transforms concepts into detailed plans that bring spaces to life.

5. Product Design:

AutoCAD also steps into product design, offering 3D tools to create prototypes that can be tested and refined. Designers can visualize and perfect their creations, ensuring they function flawlessly before production begins.

SolidWorks Applications

1. Mechanical Engineering:

SolidWorks is the backbone of mechanical design, empowering engineers to craft detailed machine parts, complex assemblies, and systems. Its simulation tools allow for real-world performance testing, ensuring designs meet stringent mechanical standards before manufacturing.

2. Product Design:

For product designers, SolidWorks is a powerhouse. From creating intricate prototypes to running stress simulations, it helps designers perfect their concepts. Its advanced tools streamline the transition from an idea to a manufacturing-ready model, saving time and resources.

3. Industrial Design:

Industrial designers turn to SolidWorks for its specialized tools for sheet metal fabrication, weldments, and injection mould design. Whether crafting consumer products or heavy machinery, the software ensures every detail aligns with production needs.

4. Aerospace:

In the aerospace sector, precision and safety are non-negotiable. SolidWorks supports these goals with tools for designing aircraft parts, testing thermal dynamics, and simulating aerodynamic performance, making it indispensable for aviation engineers.

5. Consumer Electronics:

For electronics manufacturers, SolidWorks bridges design and functionality. It helps create durable and aesthetically pleasing housings, ensuring electronic products are both functional and user-friendly.

Comparing Design Tools? Give this blog a read: Revit vs AutoCAD: The Ultimate Comparison for Design Professionals

Differences in User Interface and Ease of Use

The way software feels and functions often determines how quickly users can adapt to it. AutoCAD and SolidWorks present distinct approaches in their interfaces, each catering to specific workflows and user preferences.

AutoCAD leans heavily on its keyboard command system, a feature adored by seasoned drafters who value speed and precision. Its interface is built around 2D drafting tools, offering a workspace that feels intuitive for those familiar with traditional drafting methods. While AutoCAD does include 3D tools, they take a backseat to its 2D capabilities, making it a preferred choice for professionals who focus on creating detailed plans, layouts, and technical drawings.

SolidWorks, on the other hand, is inherently 3D-focused, with an interface that feels like a playground for mechanical engineers and product designers. Its drag-and-drop features, ribbon-based navigation, and context-sensitive menus make working on complex assemblies and components intuitive. Visual learners especially find SolidWorks easier to navigate because of its 3D-centric design. The software guides users through the creation of parts, assemblies, and simulations with workflows that feel logical and streamlined.

In essence, AutoCAD’s straightforward, command-driven layout is perfect for drafters steeped in 2D work, while SolidWorks offers a visual and interactive experience ideal for those building intricate 3D models and assemblies. The choice comes down to how you prefer to interact with your designs.

Differences in Pricing and Licensing

The cost of CAD software plays a significant role in determining which tool professionals choose, particularly in industries with tight budgets. Both AutoCAD and SolidWorks offer subscription-based pricing, catering to different user needs, but their structures and focuses differ.

AutoCAD Pricing

AutoCAD, designed for architects, engineers, and drafters, focuses heavily on 2D and 3D drafting workflows. Its pricing is as follows:

- Monthly Subscription: ₹13,540

- Annual Subscription: ₹1,10,920

- Three-Year License: ₹3,32,760

With its higher subscription costs, AutoCAD offers a robust set of features for design professionals, including cloud-based collaboration tools and wide platform compatibility.

SolidWorks Pricing

SolidWorks, tailored for 3D parametric modelling and mechanical design, provides options across multiple tiers:

- Standard Plan:

- USD 2,820/year → ~₹2,35,000/year (converted from USD, excluding taxes).

- Professional Plan:

- USD 3,456/year → ~₹2,88,000/year.

Includes an intelligent CAD library, rendering capabilities, and cost estimation tools.

- USD 3,456/year → ~₹2,88,000/year.

- Premium Plan:

- USD 4,716/year → ~₹3,92,000/year.

Offers advanced features like electrical and piping design, motion analysis, and surface flattening.

- USD 4,716/year → ~₹3,92,000/year.

These figures are approximate and may vary with exchange rates or additional taxes. SolidWorks’ pricing may seem steep, but its advanced simulation and assembly tools make it indispensable for industries like automotive, aerospace, and product design.

Difference in Workflow Integration

AutoCAD and SolidWorks play distinct yet complementary roles in design workflows, often working hand-in-hand to streamline the process from concept to production.

AutoCAD is typically the starting point for projects requiring initial layouts and detailed 2D schematics. Whether it’s an architectural floor plan, a site layout, or an engineering schematic, AutoCAD excels at creating precise, easily editable drafts. Its compatibility with a wide range of file formats allows seamless integration into subsequent design phases.

SolidWorks, on the other hand, takes the baton when the project moves to 3D design and simulation. Engineers and product designers use SolidWorks to create intricate 3D models, run simulations, and test designs under real-world conditions. It’s also the tool of choice for creating production-ready models, ensuring that every component is accurate and functional before manufacturing begins. Together, AutoCAD and SolidWorks provide a complete design-to-production workflow that bridges 2D and 3D seamlessly.

Professionals interested in excelling in automotive design can benefit from the Autodesk Certified CAD Automotive and Product Design Course. This program focuses on the skills needed to create advanced designs and tackle real-world challenges in the automotive and manufacturing industries.

Benefits of Each Software

AutoCAD is the go-to tool for professionals who rely on broad 2D workflows. Its intuitive drafting tools and compatibility across industries make it a staple for architects, civil engineers, and drafters. The ability to make quick edits and its support for diverse file types allow teams to collaborate efficiently, whether they’re working on construction plans or infrastructure layouts.

SolidWorks stands out for users in mechanical and product design. Its advanced 3D modelling capabilities are paired with powerful simulation tools, allowing engineers to test their designs under various conditions. Additionally, SOLIDWORKS CAM takes design to the next level by integrating manufacturing processes. Powered by CAMWorks, it uses rules-based technology to unify design and production in one platform. This integration connects design and manufacturing teams through a common tool and shared 3D model, enhancing collaboration and efficiency. For industries like automotive, aerospace, and industrial design, SolidWorks delivers unparalleled precision and adaptability.

In essence, AutoCAD offers versatility and ease for 2D drafting, while SolidWorks delivers power and precision for 3D modeling and integrated manufacturing. The choice depends on your project’s needs and the stage of the design process.

Final Thoughts

AutoCAD and SolidWorks, while both integral to the world of CAD, cater to vastly different audiences and project needs. AutoCAD excels in 2D drafting and broad compatibility across architecture, civil engineering, and general design industries. It’s the perfect tool for professionals who rely on precision layouts, quick edits, and a wide range of drafting applications.

SolidWorks, on the other hand, is built for those who want to dive deep into 3D modelling and mechanical design. With its advanced simulation tools and seamless integration of design and manufacturing through SOLIDWORKS CAM, it’s the go-to choice for engineers and product designers seeking to innovate and optimize their workflows.

Ultimately, the choice between AutoCAD and SolidWorks depends on your industry focus and project requirements. AutoCAD will serve you well if your work revolves around 2D schematics and versatility. However, if precision 3D modelling and production-ready design are paramount, SolidWorks is the clear winner. Understanding and aligning these strengths with your needs ensures you’ll make the most out of whichever tool you choose.

Frequently Asked Questions – AutoCAD Vs SolidWorks

AutoCAD is often considered easier to learn for beginners, especially for those focused on 2D drafting. Its command-based interface is straightforward for users familiar with traditional drafting workflows. SolidWorks, while intuitive for 3D modelling, has a steeper learning curve due to its advanced parametric and simulation tools, making it better suited for professionals in mechanical and product design.

Yes, AutoCAD supports 3D modelling but lacks SolidWorks’s advanced tools and parametric capabilities. AutoCAD’s 3D features are sufficient for basic designs but are not tailored for mechanical assemblies or simulations, which are SolidWorks’ strengths.

AutoCAD is widely used in architecture, civil engineering, and electrical design for creating 2D schematics and layouts. SolidWorks is ideal for mechanical engineering, product development, and industrial design, providing robust 3D modelling, assembly creation, and simulation capabilities for precision manufacturing.

Did you enjoy this article?