What is the Difference Between PCB Design and VLSI Design?

Jan 31, 2025 8 Min Read 2823 Views

(Last Updated)

The development of modern electronics relies heavily on PCB Design and VLSI Design. While PCB Design provides the structural and electrical backbone for electronic systems, VLSI Design involves creating intricate integrated circuits with millions or even billions of components.

Both disciplines are vital for different stages of electronic product development, yet they focus on distinct levels of functionality and scale. And, both fields demand specialized expertise and tools, reflecting the increasing complexity and miniaturization of modern electronics.

Hence, it is necessary to understand what they offer and how they differ so that you can choose your career backed with research. As a result, I have drafted this blog that explores their intricacies, applications, and interdependencies. We will first deep dive into the difference between PCB Design and VLSI Design and then move on to discussing PCB Design and VLSI Design separately so that we can better understand their differences.

Table of contents

- Key Difference Between PCB Design and VLSI Design

- Overview of PCB Design

- What is PCB Design?

- Stages in PCB Design

- Roles, Skills and Salaries in PCB Design

- Applications of PCB Design

- Top Tools in PCB Design

- Overview of VLSI Design

- What is VLSI Design?

- Stages in VLSI Design

- Roles, Skills and Salaries in VLSI Design

- Applications of VLSI Design

- Top Tools in VLSI Design

- Takeaways…

- FAQs

- What is the full form of PCB in VLSI?

- Is PCB and VLSI same?

- Is VLSI in ECE?

- Does VLSI have coding?

- What is VLSI language?

Key Difference Between PCB Design and VLSI Design

Although we will be covering everything about both these fields in detail in the overviews below, the below table is just to give you a last minute revision about the key differences and highlights of both these fields:

| Aspect | PCB Design | VLSI Design |

| Definition | PCB Design focuses on creating printed circuit boards that interconnect electronic components. | VLSI Design focuses on designing integrated circuits (ICs) with millions of transistors. |

| Scope | Involves physical layout, routing, and interconnection of components. | Includes logic design, synthesis, and physical layout of ICs. |

| Primary Components | Resistors, capacitors, diodes, transistors, and connectors mounted on a PCB. | Transistors, logic gates, memory units, and other circuit components within a chip. |

| Tools Used | CAD tools like Altium Designer, KiCAD, Eagle, OrCAD. | EDA tools like Cadence, Synopsys, Mentor Graphics, and Verilog simulators. |

| Design Output | Gerber files for PCB fabrication. | GDSII files for IC fabrication. |

| Focus | Physical design, signal integrity, and manufacturability of boards. | Logic design, performance optimization, and power efficiency of ICs. |

| Industries | Consumer electronics, automotive, and telecommunications. | Semiconductor, AI, IoT, and high-performance computing. |

| Education Requirement | Requires an understanding of electronics engineering and hands-on CAD skills. | Requires knowledge of digital design, HDL (Verilog, VHDL), and semiconductor technology. |

| Complexity | Relatively lower complexity; involves fewer layers and components. | Higher complexity; involves millions of components and intricate layouts. |

| Cost | Lower cost due to simpler fabrication processes. | High development and fabrication costs due to advanced semiconductor manufacturing. |

| Testing Methods | Involves functional testing, EMI/EMC testing, and thermal analysis. | Involves simulation, verification, and formal methods like DFT (Design for Testability). |

| Design Challenges | Signal integrity, power distribution, and thermal dissipation. | Timing optimization, power minimization, and managing parasitic effects. |

| Career Roles | PCB Design Engineer, Hardware Engineer, PCB Validation Engineer. | VLSI Design Engineer, ASIC Engineer, Physical Design Engineer, Verification Engineer. |

| Salary Range (India) | ₹3–18 LPA depending on experience. | ₹5–45 LPA depending on experience and specialization. |

| Global Trends | Essential for IoT devices, automotive electronics, and embedded systems. | Drives innovation in AI, machine learning, and next-gen processors. |

Overview of PCB Design

What is PCB Design?

PCB Design refers to creating physical boards that house and connect electronic components like resistors, capacitors, ICs, and connectors. A PCB not only holds these components in place but also facilitates electrical connections through copper traces, enabling the circuit to function as intended. PCBs form the foundation of most electronic devices, ranging from consumer gadgets to industrial machinery.

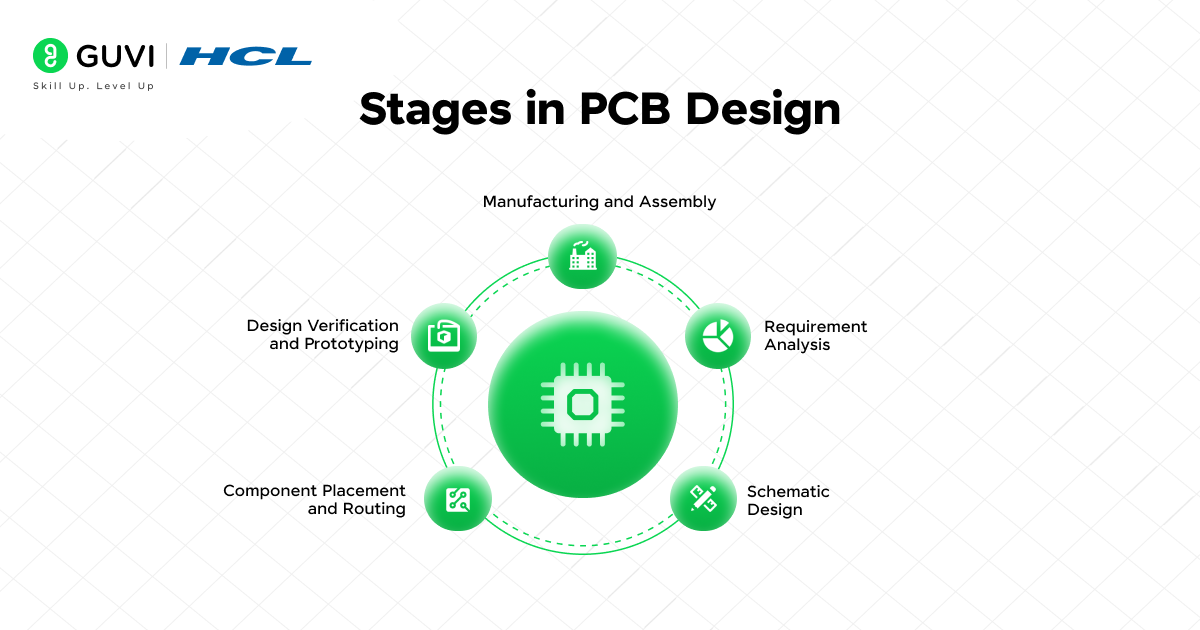

Stages in PCB Design

The process of PCB (Printed Circuit Board) design involves several critical stages to ensure the final board meets functionality, manufacturability, and performance standards. Hence it is very important for you understand the stages and given below is a detailed explanation of each stage:

1. Requirement Analysis

This stage involves defining the PCB’s purpose and specifications by collaborating with stakeholders. Engineers document the electrical, mechanical, and environmental requirements to ensure the design aligns with its intended application.

2. Schematic Design

Engineers create a schematic diagram using CAD software, translating circuit functionality into an organized blueprint. Components are selected, connected symbolically, and verified through simulations to ensure proper functionality.

3. Component Placement and Routing

Components are strategically placed on the board to optimize functionality and manufacturability, focusing on minimizing interference and ensuring thermal management. Routing follows, where copper traces connect components while maintaining signal integrity and adhering to design rules.

4. Design Verification and Prototyping

The design undergoes validation using automated tools to ensure compliance with industry standards and functional requirements. Prototypes are then manufactured and tested for functionality and performance, with adjustments made if necessary.

5. Manufacturing and Assembly

Once the design is finalized, the PCB is sent for production. Manufacturers fabricate the board, applying processes like etching, drilling, and solder masking. Components are assembled using techniques like surface-mount technology (SMT) or through-hole assembly. The final product undergoes quality control checks before deployment.

Quite the process, isn’t it? But it is necessary as these stages ensure a robust, high-performing PCB, suitable for its intended application.

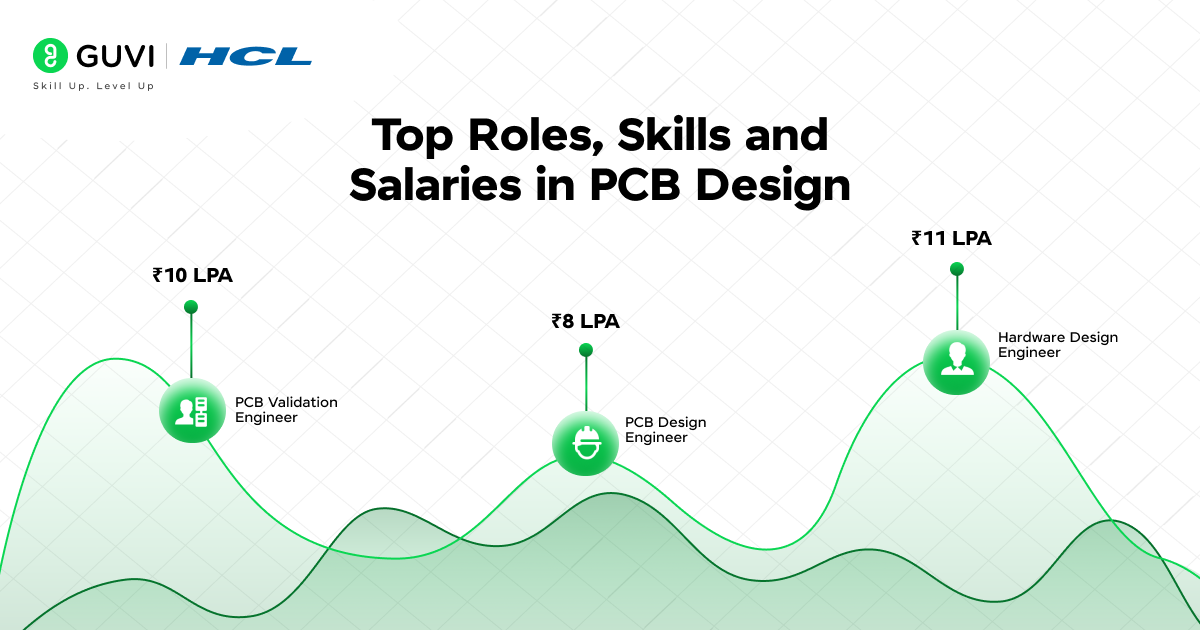

Roles, Skills and Salaries in PCB Design

Let us now discuss the top roles, their relevant skills and salaries offered in the field of PCB Design:

| Role | Description | Key Skills | Average Salary (India) |

| 1) PCB Design Engineer | They are responsible for designing and optimizing printed circuit boards for various electronic applications, including schematic design and layout creation. | – Proficiency in PCB design tools like Altium Designer, OrCAD, and KiCAD. – Expertise in signal integrity, power distribution, and thermal management. – Strong understanding of Design for Manufacturing (DFM) and Design for Assembly (DFA). – Skills in electrical circuit analysis and troubleshooting. | ₹8 LPA |

| 2) Hardware Design Engineer | These Engineers work on integrating PCB designs into broader hardware architectures, ensuring seamless interaction with other components and meeting performance benchmarks. | – Proficiency in hardware-software interfacing. – Deep knowledge of embedded systems and microcontroller integration. – Experience with hardware testing tools like oscilloscopes and multimeters. – Familiarity with EMI/EMC standards and mitigation strategies. | ₹11 LPA |

| 3) PCB Validation Engineer | They test and verify PCB functionality under real-world conditions through simulation-based testing, fault analysis, and detailed reporting. | – Expertise in automated testing tools. – Understanding of PCB manufacturing processes and materials. – Strong skills in stress testing and fault analysis. – Ability to analyze and report test outcomes effectively. | ₹10 LPA |

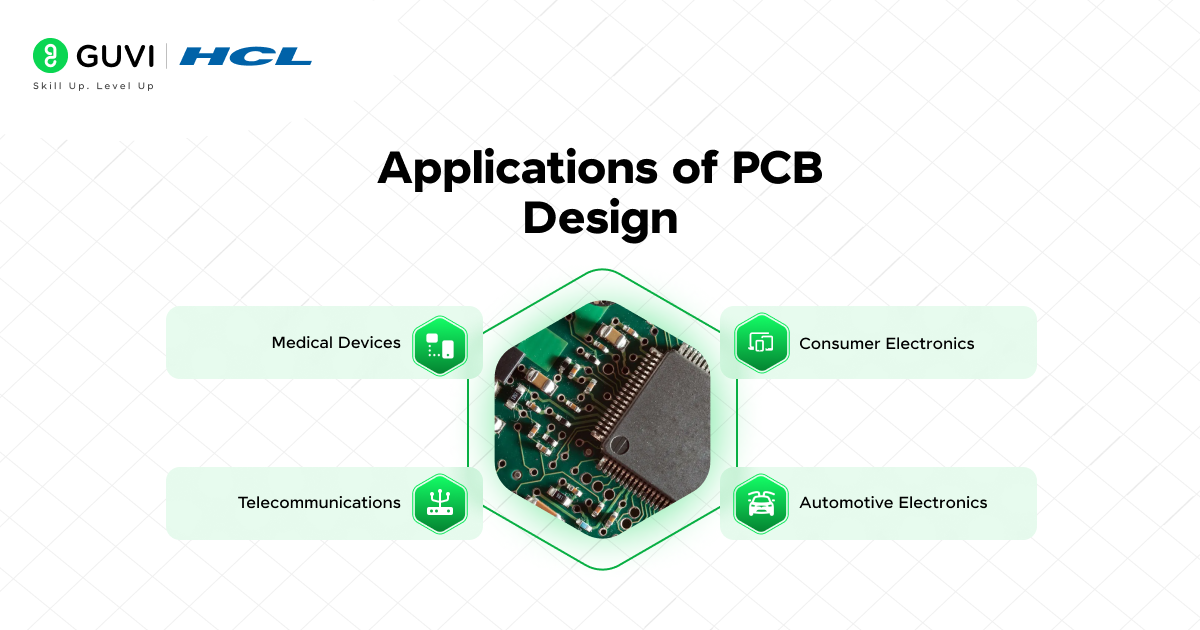

Applications of PCB Design

PCBs are central to a vast array of electronic products and hence it is necessary for you to understand how they are used in the real world:

1. Consumer Electronics

In the consumer electronics sector, PCBs are integral to the functioning of everyday devices such as smartphones, laptops, tablets, and wearable gadgets. These devices rely on multi-layered PCBs to integrate components like processors, memory modules, sensors, and batteries into compact, efficient designs.

As technology advances, the miniaturization of components demands even more complex PCB designs, which allow these devices to perform high-functioning tasks while maintaining a sleek form factor. The design also addresses heat dissipation and signal integrity, ensuring that components function optimally without interference.

2. Automotive Electronics

The automotive industry extensively uses PCBs to manage and enhance vehicle functionality. From engine control units (ECUs) to safety systems like anti-lock braking systems (ABS), PCBs form the backbone of modern vehicle electronics. They are also found in infotainment systems, navigation modules, and advanced driver-assistance systems (ADAS), which rely on high-speed processing and robust communication capabilities.

Automotive PCBs need to meet strict standards, as they must function reliably in high-vibration environments and withstand extreme temperatures, ensuring long-term durability and safety.

3. Medical Devices

Medical devices benefit significantly from PCB technology, as they often require precise and reliable electronics for critical functions. Devices such as heart rate monitors, pacemakers, MRIs, and blood glucose meters rely on compact and accurate PCB designs to monitor health conditions in real time.

The medical industry also demands high-density interconnect (HDI) PCBs, which allow for more components in a smaller space, ideal for portable and implantable devices. The reliability and performance of these devices directly impact patient safety, making PCB design an essential part of medical device development.

4. Telecommunications

In telecommunications, PCBs are used in a wide range of equipment that supports both wired and wireless communication networks. Routers, servers, base stations, and mobile devices all rely on the performance of PCBs to transmit data at high speeds.

For instance, PCBs in 5G infrastructure must handle high-frequency signals and provide minimal latency to ensure uninterrupted, high-speed internet connections. The design of these PCBs requires attention to signal integrity and electromagnetic interference (EMI), as any disturbance in the signal path can lead to data loss or system failures

Top Tools in PCB Design

Now, we will discuss the top tools used in PCB design, highlighting their features, applications, and significance. It is important that you know them as you will need to learn to use them:

1. Altium Designer

Altium Designer is one of the most comprehensive and widely used PCB design tools, known for its unified design environment. It integrates schematic capture, PCB layout, and simulation features seamlessly.

Its advanced features include a 3D design interface, real-time collaboration, and extensive libraries of components, making it ideal for high-speed and complex PCB designs hence making it important for you to learn to see this one.

2. KiCAD

KiCAD is an open-source PCB design tool that offers a robust suite of features for schematic capture, PCB layout, and Gerber file generation. It is particularly favored by small-scale developers and hobbyists due to its cost-free model and community-driven updates. KiCAD supports multilayer boards and offers a 3D viewer for visualizing the final design.

3. OrCAD

OrCAD, developed by Cadence, is renowned for its powerful simulation capabilities and precise PCB layout features. It is widely used in industries requiring high reliability, such as aerospace and automotive. OrCAD excels in signal integrity analysis, power distribution network (PDN) analysis, and integrating with other Cadence tools for a streamlined design-to-manufacturing process.

4. Eagle (Easily Applicable Graphical Layout Editor)

Eagle, now part of Autodesk, is a beginner-friendly PCB design tool that also caters to professionals. Its user-friendly interface and robust library of parts make it popular for designing small to medium-sized PCBs. Eagle’s AutoRouter and integration with Autodesk Fusion 360 provide an added advantage for electromechanical designs.

5. Allegro PCB Designer

Allegro PCB Designer, another Cadence product, is a professional-grade tool tailored for advanced and large-scale PCB designs. It specializes in high-speed and high-density layouts, offering powerful features like constraint-driven design and real-time electrical rule checking. It is widely used for PCBs in data centers, telecommunications, and server technologies.

Overview of VLSI Design

What is VLSI Design?

Now that we’ve covered PCB Design, let’s move onto learning about VLSI Design which will then help us in understanding how these two fields differ.

VLSI Design is the process of integrating millions or billions of transistors onto a single silicon chip. These chips, known as integrated circuits (ICs), perform computational tasks like data processing, memory storage, and communication. VLSI design has revolutionized electronics by enabling high-performance devices in compact forms, from microprocessors to System-on-Chip (SoC) architectures.

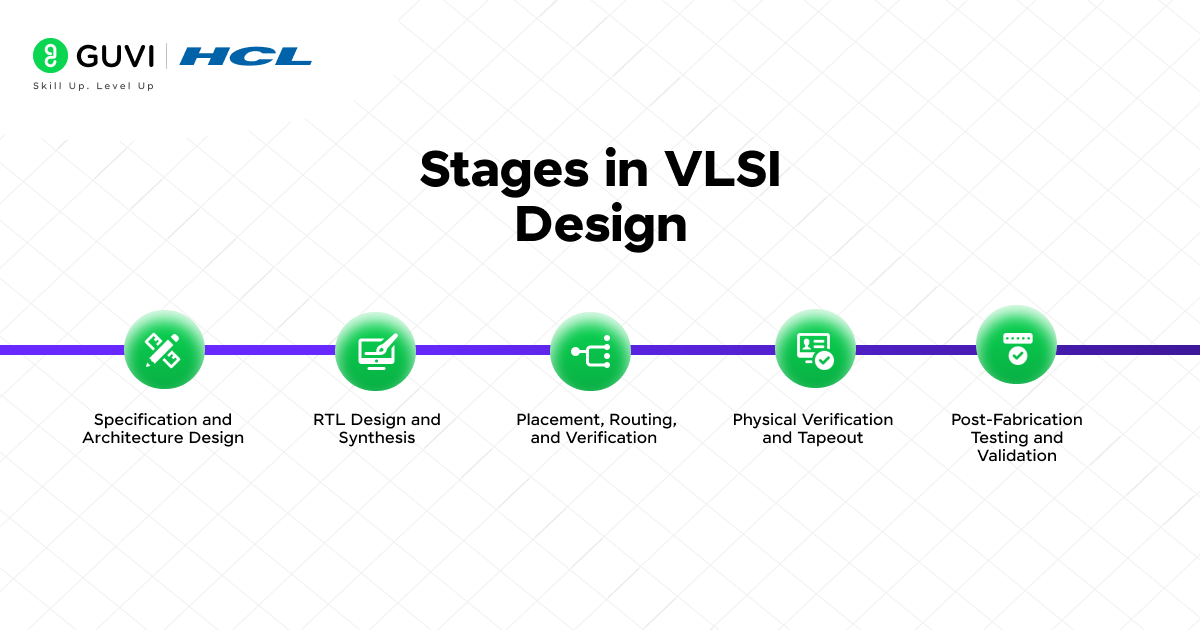

Stages in VLSI Design

1. Specification and Architecture Design

The design process begins with defining system specifications such as performance, power consumption, and size. The architecture is conceptualized, outlining how components interact and divide into sub-modules. This blueprint ensures the design meets performance criteria while optimizing for area and power.

2. RTL Design and Synthesis

Using HDLs like Verilog or VHDL, the chip’s behavior is described at the Register Transfer Level (RTL), defining how data moves and processes across the chip. This RTL design is then converted into a gate-level netlist through synthesis, optimizing the design for area, timing, and power.

3. Placement, Routing, and Verification

The physical layout of components is determined (placement), and connections between them are created (routing). Techniques like wire-length optimization ensure performance criteria are met. Simultaneously, verification ensures the design functions correctly, including functional, timing, and formal verification.

4. Physical Verification and Tapeout

Design Rule Checking (DRC) and Layout Versus Schematic (LVS) ensure the layout complies with manufacturing rules. Once verified, the finalized design is sent to the foundry as a GDSII file for fabrication, marking the tapeout stage.

5. Post-Fabrication Testing and Validation

After fabrication, the chip undergoes real-world testing to validate its functionality, performance, and reliability. Chips that meet quality standards are mass-produced, tested for defects, and prepared for distribution.

Would you like to master VLSI Design and become a pro at designing chips? GUVI’s VLSI Design and Verification Course will be the perfect resource for you with its hands-on learning in digital design, verification, RTL coding, and simulation using industry-standard tools like Verilog and SystemVerilog.

Taught by experienced mentors, it equips you with real-world skills to excel in the semiconductor industry. With live projects, job assistance, and a structured curriculum, this course is your gateway to mastering VLSI Design.

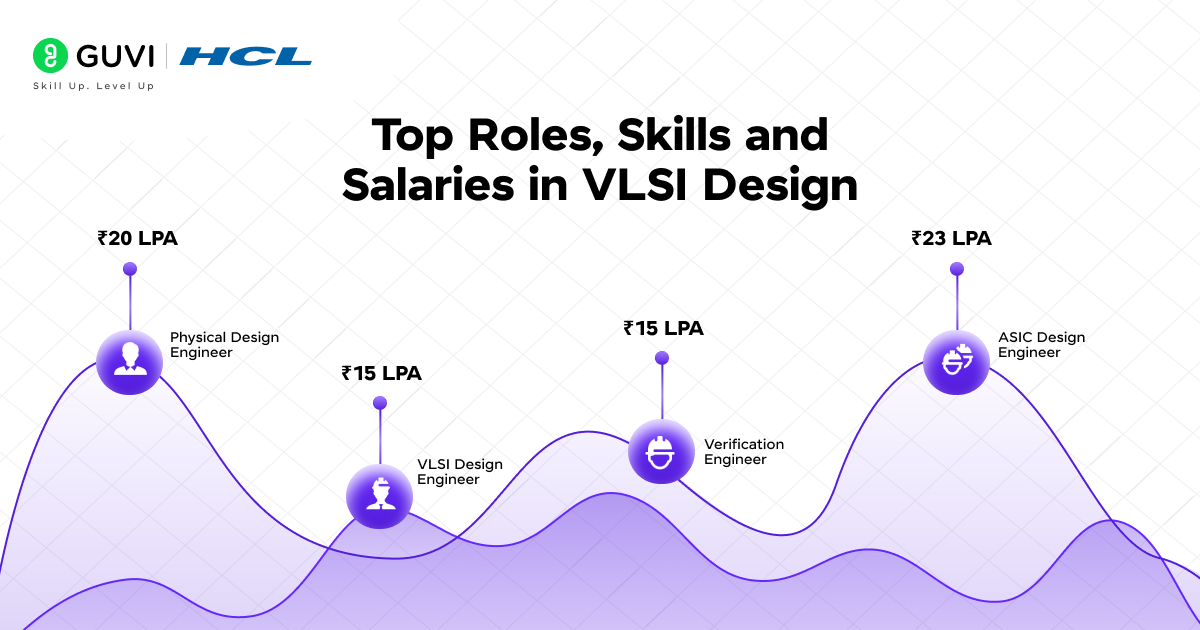

Roles, Skills and Salaries in VLSI Design

Let us now discuss the top roles, their relevant skills and salaries offered in the field of VLSI Design, this will help you understand where you can take your career:

| Role | Description | Key Skills | Average Salary (India) |

| 1) VLSI Design Engineer | Designs integrated circuits at the register-transfer level (RTL), creating logic circuits that meet performance, power, and area (PPA) constraints. | – Proficiency in HDLs like Verilog and VHDL – Understanding of synthesis, timing analysis, and power optimization – Knowledge of EDA tools like Synopsys- Strong debugging skills | ₹15 LPA |

| 2) Physical Design Engineer | Translates logical designs into optimized physical layouts for chip fabrication, ensuring performance and power efficiency. | – Proficiency in tools like Cadence Virtuoso – Expertise in placement, routing, and parasitic extraction – Knowledge of semiconductor manufacturing processes – Strong analytical skills | ₹20 LPA |

| 3) Verification Engineer | Ensures chip designs meet specifications through functional and system-level testing, utilizing simulation-based verification methodologies. | – Expertise in UVM- Proficiency in SystemVerilog for testbench creation – Knowledge of formal verification and coverage analysis – Familiarity with debugging tools like DVE and Verdi | ₹15 LPA |

| 4) ASIC Design Engineer | Designs application-specific integrated circuits (ASICs) for industries like automotive, IoT, and telecommunication, ensuring functional reliability. | – Proficiency in tools like Cadence Innovus – Understanding of low-power design techniques – Experience with chip-level design verification – Knowledge of CTS and timing closure | ₹23 LPA |

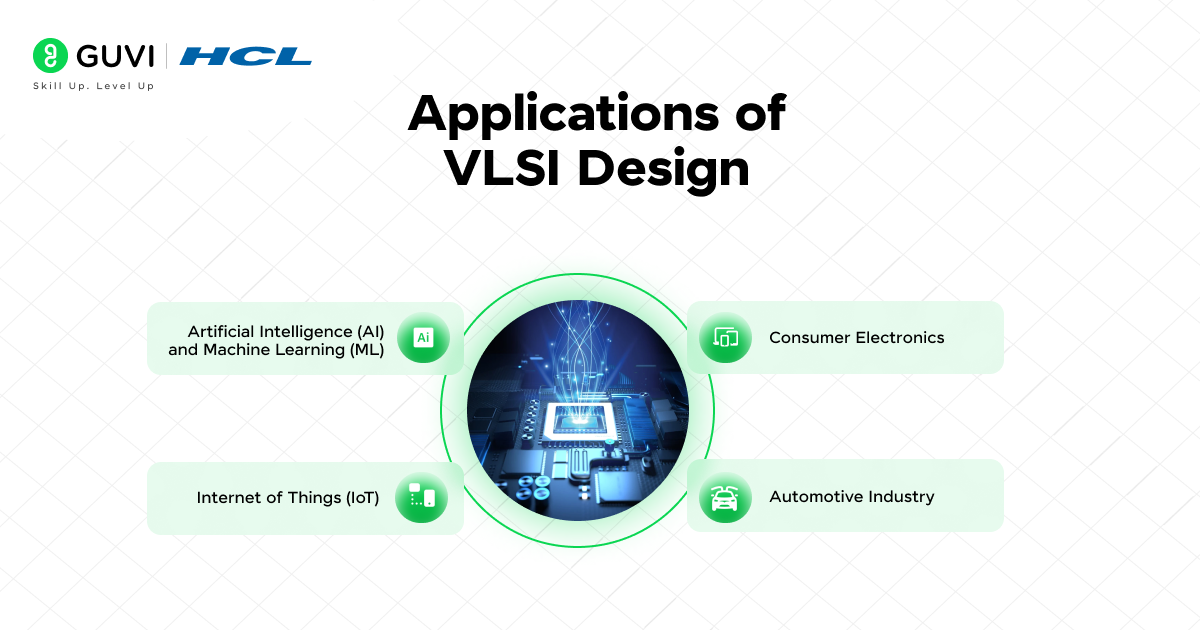

Applications of VLSI Design

VLSI (Very Large Scale Integration) design is foundational to numerous advanced technologies and industries. Below are some of the key applications of VLSI design, each explained in detail so that you know how vlsi design is applied in real life:

1. Consumer Electronics

VLSI technology powers devices like smartphones, laptops, tablets, and smart TVs. Integrated circuits (ICs) designed using VLSI principles are responsible for managing essential functionalities, such as processors for computation, memory units for data storage, and connectivity modules for communication.

For instance, system-on-chips (SoCs) in smartphones integrate processors, GPUs, and modems, enabling compact, efficient, and high-performance designs.

2. Automotive Industry

The automotive sector leverages VLSI for advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs). Chips designed using VLSI optimize performance, safety, and efficiency in vehicles. Examples include radar systems for adaptive cruise control, ICs for electric vehicles’ battery management systems, and processors for autonomous driving technologies.

3. Artificial Intelligence (AI) and Machine Learning (ML)

Specialized ICs, such as AI accelerators, GPUs, and TPUs (Tensor Processing Units), are designed using VLSI to handle complex computations required for AI and ML workloads. These chips are used in data centers for model training and inference and in edge devices for real-time AI applications like facial recognition, language processing, and autonomous robotics.

4. Internet of Things (IoT)

VLSI design enables the development of ultra-low-power ICs for IoT devices like smart home systems, wearable technology, and industrial sensors. These chips integrate processors, communication modules, and power management circuits to ensure reliability, compactness, and energy efficiency.

For example, VLSI chips in smartwatches combine Bluetooth connectivity, biometric sensors, and real-time processing.

Top Tools in VLSI Design

Now, we will discuss the top tools used in VLSIdesign, highlighting their features, applications, and significance. It is important that you know them as you will need to learn to use them:

1. Cadence Virtuoso

Cadence Virtuoso is one of the most widely used tools for custom IC design and analog/mixed-signal design. It allows designers to create complex layouts, simulate, and verify designs. The tool provides a comprehensive platform for circuit design, layout generation, and verification, supporting a variety of processes such as analog-to-digital conversion, RF design, and power management.

Its advanced layout automation capabilities make it essential for designing high-performance, low-power chips, particularly in industries like telecommunications and automotive.

2. Synopsys Design Compiler

Synopsys Design Compiler is an RTL synthesis tool used to convert high-level hardware descriptions written in VHDL or Verilog into gate-level representations. It is highly efficient in optimizing the performance, area, and power of a design while ensuring compliance with design constraints.

The tool integrates easily into the design flow for ASIC and FPGA designs, helping engineers achieve the optimal timing closure and area utilization for their chips.

3. Mentor Graphics Calibre

Mentor Graphics Calibre is a physical verification tool that checks the layout design against manufacturing constraints. It helps ensure that the layout is DRC (Design Rule Check) and LVS (Layout Versus Schematic) compliant, which is critical in ensuring manufacturability and functional correctness of ICs.

Calibre plays a pivotal role in the signoff phase of the VLSI design process, preventing errors during fabrication and improving the yield of silicon chips.

4. Xilinx Vivado

Xilinx Vivado is a design suite used primarily for FPGA (Field Programmable Gate Array) development. It allows VLSI designers to implement complex designs by providing comprehensive tools for RTL synthesis, simulation, and implementation.

Vivado’s high-level synthesis (HLS) capabilities allow designers to optimize hardware designs from high-level programming languages like C and C++. This tool is extensively used in prototyping and for designs in embedded systems, telecommunications, and high-speed data transfer applications.

5. Synopsis HSPICE

HSPICE is a powerful simulation tool used for circuit simulation in VLSI design. It is used for analyzing analog and mixed-signal circuits, providing insights into power consumption, delay, noise, and other electrical parameters.

HSPICE allows for accurate performance modeling of both digital and analog circuits at the transistor level, making it an indispensable tool for designers working on low-power or high-performance ICs. Its ability to handle complex waveform analysis and timing analysis makes it ideal for signal integrity analysis.

Takeaways…

In conclusion, PCB Design and VLSI Design are foundational components of modern electronics, each serving a unique but interdependent role. Understanding these technologies and their interrelations is crucial for advancing innovation in electronics and I hope this article has helped in doing the same.

As technology continues to advance, particularly in fields like 5G, AI, and IoT, the collaboration between VLSI and PCB design becomes increasingly crucial for the development of cutting-edge electronics.

In conclusion, a successful electronic product depends not only on the complexity and capability of the VLSI circuits but also on the precision and optimization of the PCB design that supports it. Both fields are indispensable, and mastering the synergy between them is key to advancing the future of electronics.

FAQs

PCB stands for Printed Circuit Board in VLSI, which is used for connecting and supporting electronic components in circuits.

No, PCB (Printed Circuit Board) and VLSI (Very-Large-Scale Integration) are different. PCB is a physical board for connecting components, while VLSI refers to the process of integrating millions of transistors onto a single chip.

Yes, VLSI (Very-Large-Scale Integration) is a specialization within Electronics and Communication Engineering (ECE).

Yes, VLSI design involves coding, typically in hardware description languages (HDLs) like VHDL or Verilog to design circuits.

VLSI languages include VHDL (VHSIC Hardware Description Language) and Verilog, used for designing and modeling electronic systems.

![Top 8 VLSI Design Job Roles [2025] 12 vlsi design job roles](https://www.guvi.in/blog/wp-content/uploads/2025/03/Top-8-VLSI-Design-Job-Roles.png)

Did you enjoy this article?