Top 75 CAD Interview Questions and Answers

Mar 20, 2025 13 Min Read 8184 Views

(Last Updated)

Breaking into the competitive computer-aided design (CAD) field calls for a strong command of industry tools, techniques, and creative problem-solving. This blog compiles a comprehensive collection of CAD Interview questions and answers, covering key areas like 2D and 3D modeling, parametric design, and the latest advancements in CAD technology.

From fresh graduates to seasoned professionals, preparing with these CAD job interview questions can help you stand out in interviews. By honing your skills and gaining insights into real-world applications, you’ll be ready to showcase your technical expertise and secure exciting opportunities in the industry.

Table of contents

- CAD Interview Questions and Answers

- What is CAD, and why is it important in modern design and engineering?

- How do you ensure the accuracy and precision of your CAD designs?

- What are the primary differences between 2D and 3D CAD?

- What types of constraints are commonly used in CAD software, and how do they work?

- Can you explain the concept of parametric modeling in CAD?

- How do you handle collaborative design projects using CAD software?

- What are some challenges you’ve faced in CAD design, and how did you overcome them?

- What is the purpose of using layers in CAD software?

- How do you prepare CAD files for 3D printing?

- What trends in CAD design are shaping the future of the industry?

- What is the role of CAD software in prototyping and product development?

- How do you troubleshoot errors in a CAD design?

- What are Boolean operations in CAD, and how are they used?

- How do you ensure compliance with design standards in your CAD projects?

- What is the significance of rendering in CAD?

- What are the benefits of parametric modeling over direct modeling?

- How do CAD tools integrate with manufacturing processes?

- What strategies do you use to manage large and complex CAD files?

- What advancements in CAD technology do you think will shape the industry in the next 5 years?

- What are some key considerations when designing for manufacturability in CAD?

- How do you approach creating assemblies in CAD software?

- Can you describe the role of simulation tools in CAD design?

- What are some common file formats used in CAD, and what are their purposes?

- How do you handle multiple revisions in a CAD project?

- What steps do you take to optimize CAD designs for 3D printing?

- What is the significance of geometric tolerances in CAD?

- How do you ensure effective collaboration on CAD projects with remote teams?

- What are the benefits of using cloud-based CAD software?

- How do you integrate sustainability considerations into CAD designs?

- What are design constraints, and how do you address them in CAD projects?

- How do you utilize macros in CAD software to improve efficiency?

- Can you explain the difference between surface modeling and solid modeling in CAD?

- What is reverse engineering, and how is CAD used in this process?

- How do you incorporate industry standards into your CAD designs?

- What is the purpose of a digital twin in CAD, and how is it created?

- How do you ensure effective documentation of CAD projects?

- What are some methods to simplify complex CAD models?

- How do you approach troubleshooting compatibility issues between different CAD software?

- What role does CAD play in generative design?

- What is the role of sketching in CAD, and how do you ensure precision while sketching?

- How do you manage design changes late in the development cycle?

- What are some common challenges in creating assemblies, and how do you address them?

- How do you ensure that a CAD design is optimized for cost-efficiency?

- What is the significance of Bill of Materials (BOM) in CAD, and how do you generate it?

- What is topology optimization, and how is it applied in CAD?

- How do you prepare CAD files for client presentations?

- What steps do you take to ensure your CAD models are compatible with CNC machines?

- What is the importance of feature-based modeling in CAD?

- How do you handle confidentiality and security of CAD designs?

- What is the role of constraints in maintaining design integrity in CAD?

- How do you use exploded views in CAD projects?

- What are some common CAD modeling techniques for creating complex curves or surfaces?

- How do you incorporate motion analysis into CAD designs?

- What is a sectional view, and why is it important in CAD drawings?

- How do you create standardized templates in CAD software?

- How do you ensure that your CAD designs are accessible to non-technical stakeholders?

- What is the difference between additive and subtractive manufacturing in CAD, and how does CAD facilitate both?

- What is design intent, and how do you maintain it in CAD projects?

- How do you use CAD tools to estimate material usage and costs?

- What are dynamic blocks in AutoCAD, and how do you use them?

- How do you approach designing for modularity in CAD projects?

- What are the benefits of using feature trees in CAD software, and how do you utilize them?

- How do you use CAD to ensure proper clearances and tolerances in mechanical designs?

- How do you create a 3D model in AutoCAD?

- What is the difference between raster and vector graphics in CAD?

- What is the purpose of XREF (External References) in AutoCAD, and how do you manage them?

- How do you implement design reuse in CAD projects?

- What are some methods for enhancing CAD design visualization?

- How do you ensure scalability in CAD designs for future updates or expansions?

- What is the importance of wireframe modeling in CAD, and when do you use it?

- How do you use CAD software to create technical documentation?

- How do you integrate CAD designs into BIM (Building Information Modeling) workflows?

- What strategies do you use for handling large assemblies in CAD software?

- What is the purpose of dimensioning in CAD, and how do you apply it?

- Wrapping Up

- Frequently Asked Questions

- What are the most commonly asked questions in a CAD job interview?

- How can I prepare effectively for CAD job interviews?

- Do CAD interviews require practical demonstrations?

- What key skills do interviewers look for in CAD candidates?

CAD Interview Questions and Answers

According to Statista, the global computer-aided design (CAD) market is expected to reach approximately 14 billion US Dollars in size. This upward trend is driven by the rising demand for 3D CAD software across various industries, including automotive, aerospace, and manufacturing.

Our thoughtfully compiled list of CAD interview questions and answers will guide you through some key areas and prepare you to effectively address any set of technical challenges that might be shot across your way!

1. What is CAD, and why is it important in modern design and engineering?

CAD (Computer-Aided Design) is the use of computer software to create, modify, analyze, and optimize designs. It is vital in modern engineering and design because it enhances accuracy, efficiency, and collaboration. CAD software allows designers to visualize complex models, simulate real-world scenarios, and make iterative improvements without the need for physical prototypes. It is widely used across industries like architecture, manufacturing, and automotive engineering.

2. How do you ensure the accuracy and precision of your CAD designs?

Accuracy in CAD designs is ensured through a combination of best practices and software tools. I always start by setting the correct units and scales, enabling snap-to-grid functionality, and using geometric constraints for precise alignment. Regularly checking dimensions and tolerances against project specifications is another key step. Additionally, I conduct a final quality check by reviewing the design in both 2D and 3D views to identify any inconsistencies.

3. What are the primary differences between 2D and 3D CAD?

2D CAD focuses on creating two-dimensional drawings, such as floor plans or technical schematics, using lines, arcs, and text annotations. It is ideal for simple layouts and technical documentation. In contrast, 3D CAD allows for the creation of three-dimensional models, enabling designers to visualize objects from multiple perspectives. This approach is useful for creating complex assemblies, performing simulations, and generating realistic renderings.

4. What types of constraints are commonly used in CAD software, and how do they work?

Common constraints in CAD software include geometric and dimensional constraints. Geometric constraints, like parallel, perpendicular, tangent, and concentric, define relationships between geometric entities. Dimensional constraints specify exact measurements, such as lengths, angles, and radii. These constraints ensure that changes to one part of the design automatically update related components, maintaining design integrity.

5. Can you explain the concept of parametric modeling in CAD?

Parametric modeling is a CAD technique where design elements are defined by parameters or variables. For example, dimensions like length, width, and height can be adjusted to automatically update the entire model. This method is highly flexible, enabling quick design modifications and promoting consistency across the model. It is widely used in industries where frequent design iterations are required.

6. How do you handle collaborative design projects using CAD software?

Collaboration in CAD projects often involves sharing files, integrating feedback, and coordinating with team members. I use cloud-based platforms or software with version control to ensure that all team members work on the latest file versions. By organizing designs into layers and assigning roles for edits, I maintain clarity and avoid overwriting. Regular check-ins and sharing design updates also help streamline the collaborative process.

7. What are some challenges you’ve faced in CAD design, and how did you overcome them?

One challenge I encountered was managing a large and complex assembly with hundreds of components. It was difficult to ensure that all parts aligned correctly without slowing down the software. I overcame this by breaking the assembly into smaller sub-assemblies, optimizing file sizes, and leveraging software features like suppressing unused components. This approach improved performance and maintained accuracy.

8. What is the purpose of using layers in CAD software?

Layers in CAD software help organize and manage different elements of a design. For example, architectural plans may have separate layers for walls, furniture, and electrical systems. Layers allow designers to control the visibility, color, and line style of specific elements, making it easier to focus on specific parts of the design. They also simplify edits and reduce the risk of accidental changes.

9. How do you prepare CAD files for 3D printing?

Preparing CAD files for 3D printing involves converting the model into a compatible file format, such as STL. I ensure that the design is watertight, meaning there are no gaps or overlapping surfaces. Checking the model’s dimensions and scale is essential to match the printer’s capabilities. I also use slicing software to set parameters like layer height, infill density, and support structures before printing.

10. What trends in CAD design are shaping the future of the industry?

Trends like AI-assisted design, generative design, and cloud-based collaboration are transforming the CAD industry. AI tools help automate repetitive tasks, while generative design uses algorithms to explore multiple design options based on constraints. Cloud-based platforms enable real-time collaboration and access to designs from anywhere. Staying updated on these trends is crucial for CAD professionals to remain competitive.

11. What is the role of CAD software in prototyping and product development?

CAD software plays a crucial role in prototyping and product development by allowing designers to create detailed models, test designs virtually, and make iterative changes without physical prototypes. This saves time and reduces costs. CAD also integrates with simulation tools to analyze stress, thermal behavior, and other factors, ensuring the product meets performance standards before production.

12. How do you troubleshoot errors in a CAD design?

When errors occur in CAD designs, I start by identifying the issue through diagnostic tools within the software, such as error checkers or preview modes. Next, I review constraints, dimensions, or overlapping geometry that might be causing the problem. For complex errors, I refer to project documentation or consult with team members to resolve conflicts. Finally, I run a test iteration to confirm the fix.

13. What are Boolean operations in CAD, and how are they used?

Boolean operations are used to combine or modify 3D models by performing operations such as Union, Subtract, and Intersect. For example, the Union operation merges two solids into one, while Subtract removes the volume of one solid from another. These tools are invaluable for creating complex geometries or combining multiple components into a cohesive model.

14. How do you ensure compliance with design standards in your CAD projects?

To ensure compliance, I reference relevant industry standards and guidelines during the design process. I use CAD templates and libraries preloaded with standard components, adhere to specified tolerances, and cross-check designs with regulatory requirements. Additionally, I perform regular reviews and audits of the design to ensure accuracy and alignment with standards.

15. What is the significance of rendering in CAD?

Rendering transforms basic CAD models into photorealistic images or animations by simulating light, textures, and materials. It is essential for visualizing designs in a realistic context, communicating ideas to stakeholders, and identifying potential design flaws early. Rendering is commonly used in industries like architecture, automotive, and product design.

Before we move into the next section, we’d like to ensure you are well-versed in the essentials of civil engineering. To smoothen your learning process, consider enrolling in GUVI’s IITM-Pravartak and Autodesk-certified Expert in CAD Building Design and Analysis Course. You’ll gain hands-on knowledge in this premium Zen program and get access to fundamental tools such as AutoCAD, Revit, 3dsMax, etc, needed for modern civil design.

Additionally, if you want to get started in the field through self-paced learning, try GUVI’s AutoCAD Civil Course.

16. What are the benefits of parametric modeling over direct modeling?

Parametric modeling allows designers to define relationships between design elements using parameters like dimensions and constraints. Changes to one parameter automatically update the related elements, ensuring consistency. Direct modeling, while quicker for one-off adjustments, lacks this flexibility and consistency. Parametric modeling is ideal for iterative designs and projects requiring frequent updates.

17. How do CAD tools integrate with manufacturing processes?

CAD tools integrate seamlessly with manufacturing processes through features like generating CNC machining instructions, creating STL files for 3D printing, and producing detailed technical drawings for fabrication. This integration ensures that designs transition smoothly from the digital space to physical production, reducing errors and enhancing efficiency.

18. What strategies do you use to manage large and complex CAD files?

Managing large CAD files involves using layers and sub-assemblies to simplify navigation and editing. I optimize file sizes by removing unnecessary details and compressing data where possible. Using software features like suppressing components and using lightweight representations also helps improve performance when working with complex models.

19. What advancements in CAD technology do you think will shape the industry in the next 5 years?

Advancements like AI-driven design tools, cloud-based CAD platforms, and augmented reality (AR) for visualization are set to shape the industry. AI tools can enhance productivity by automating repetitive tasks, while AR enables real-time interaction with 3D models. Additionally, cloud platforms facilitate smoother collaboration across global teams.

20. What are some key considerations when designing for manufacturability in CAD?

Designing for manufacturability (DFM) involves ensuring that a design can be efficiently produced without complications. Key considerations include:

- Material Selection: Choose materials that are readily available and compatible with manufacturing processes.

- Simplified Geometry: Avoid unnecessary complexity to reduce machining time and cost.

- Tolerances: Define clear and achievable tolerances to maintain quality without driving up production costs.

- Standardized Components: Use standard parts where possible to minimize production time.

- Assembly Feasibility: Ensure components can be easily assembled with minimal adjustments.

21. How do you approach creating assemblies in CAD software?

Creating assemblies in CAD involves importing individual parts and defining their relationships to build a complete system. I use features like mates, constraints, and joints to align and connect components accurately. Regular validation of clearances and interference checks ensures proper fit and functionality. I also utilize exploded views for visualizing assembly sequences.

22. Can you describe the role of simulation tools in CAD design?

Simulation tools in CAD allow designers to test and validate designs virtually. They can analyze factors like stress, heat transfer, and motion to predict how a product will perform under real-world conditions. By identifying potential flaws early, simulation reduces the need for costly physical prototypes and helps optimize designs for performance and safety.

23. What are some common file formats used in CAD, and what are their purposes?

Common CAD file formats and their purposes include:

- DWG: Widely used for 2D and 3D drawings, compatible with AutoCAD.

- STL: Standard for 3D printing, representing models as triangular facets.

- STEP/IGES: Neutral formats for exchanging 3D data between different CAD software.

- DXF: A simplified format for sharing CAD drawings across platforms.

- PDF: Used for sharing CAD drawings in a readable format without needing CAD software.

24. How do you handle multiple revisions in a CAD project?

Managing revisions involves version control and clear documentation. I create separate files for each iteration, labeled with version numbers and change descriptions. Regularly saving and backing up designs ensures no work is lost. I also use CAD software’s revision history or external tools like PLM (Product Lifecycle Management) systems to track changes systematically.

25. What steps do you take to optimize CAD designs for 3D printing?

To optimize CAD designs for 3D printing:

- Check Wall Thickness: Ensure the model has sufficient wall thickness for structural integrity.

- Avoid Overhangs: Minimize overhangs that may require excessive support structures.

- Simplify Geometry: Reduce unnecessary details to avoid print errors.

- File Conversion: Export the design to an STL format with the appropriate resolution.

- Test Slicing: Use slicing software to preview the print and adjust parameters like layer height.

26. What is the significance of geometric tolerances in CAD?

Geometric tolerances define allowable variations in the shape, orientation, and location of features in a design. They ensure that parts fit together correctly despite minor imperfections in manufacturing. Proper tolerances help balance functionality and production feasibility while minimizing costs.

27. How do you ensure effective collaboration on CAD projects with remote teams?

I ensure effective collaboration by using cloud-based CAD platforms that allow real-time sharing and editing. Communication tools like video conferencing and shared documentation platforms help maintain clarity. Assigning roles and responsibilities and conducting regular progress reviews ensure everyone stays aligned.

28. What are the benefits of using cloud-based CAD software?

Cloud-based CAD software offers several benefits:

- Accessibility: One can access designs from anywhere with an internet connection.

- Collaboration: Multiple users can work on the same design in real time.

- Cost-Effectiveness: There’s a reduced need for powerful hardware as processing is cloud-based.

- Automatic Updates: One can always have access to the latest software features.

- Data Security: Built-in backup and version control protect against data loss.

29. How do you integrate sustainability considerations into CAD designs?

Sustainability in CAD design involves choosing eco-friendly materials, reducing waste, and optimizing manufacturing processes. I use simulation tools to analyze energy consumption and material efficiency. Additionally, I design components for recyclability and modularity, ensuring they can be easily reused or replaced.

30. What are design constraints, and how do you address them in CAD projects?

Design constraints are limitations or requirements that a project must adhere to, such as size, weight, cost, and material specifications. In CAD projects, I address these constraints by incorporating them into the initial design parameters. For instance, I use parametric modeling to adjust dimensions dynamically and run simulations to ensure the design meets functional and performance criteria within the given constraints.

31. How do you utilize macros in CAD software to improve efficiency?

Macros are scripts that automate repetitive tasks in CAD software. I create macros to perform actions like generating standard components, applying specific dimensions, or running batch processes. This reduces manual effort, minimizes errors, and significantly speeds up the design process, especially for recurring tasks.

32. Can you explain the difference between surface modeling and solid modeling in CAD?

Surface modeling focuses on creating a 3D representation of an object’s outer surface, often used for visualizing complex shapes or aesthetic designs. It does not include volume information. Solid modeling, on the other hand, creates a complete 3D object with both surface and volume information, making it suitable for engineering analysis and manufacturing.

33. What is reverse engineering, and how is CAD used in this process?

Reverse engineering involves analyzing a physical object to recreate its digital design. In CAD, this is done using tools like 3D scanning to capture the object’s geometry. The scanned data is then processed into a CAD model, which can be modified, optimized, or used to create new versions of the object.

34. How do you incorporate industry standards into your CAD designs?

To ensure compliance with industry standards, I use CAD templates preloaded with standardized settings, symbols, and components. I also cross-reference design requirements with regulatory guidelines and collaborate with quality assurance teams to verify adherence. Additionally, I stay updated on changes in industry standards to ensure my designs remain relevant.

35. What is the purpose of a digital twin in CAD, and how is it created?

A digital twin is a virtual representation of a physical product, process, or system. It is created using CAD software by incorporating real-world data from sensors, simulations, and other sources. Digital twins are used for monitoring performance, predicting maintenance needs, and optimizing designs by simulating real-world conditions.

36. How do you ensure effective documentation of CAD projects?

Effective documentation involves creating detailed drawings, annotations, and specifications that accompany the CAD model. I use title blocks to include essential project details, layers to organize elements, and callouts for clarity. Exporting designs in multiple formats, such as PDF and STEP files, ensures compatibility and accessibility for stakeholders.

37. What are some methods to simplify complex CAD models?

Simplifying complex CAD models can involve:

- Reducing unnecessary details, such as small features or internal components.

- Using lightweight representations for assemblies.

- Breaking the model into sub-assemblies to improve manageability.

- Suppressing or hiding components that are not immediately relevant.

- Leveraging software features like defeaturing tools to streamline the model.

38. How do you approach troubleshooting compatibility issues between different CAD software?

When encountering compatibility issues, I start by converting files into neutral formats like STEP or IGES to maintain data integrity. I use translation tools to ensure proper import/export settings. For recurring compatibility challenges, I document the most effective workflows and coordinate with other team members to establish consistent practices.

39. What role does CAD play in generative design?

Generative design in CAD involves using algorithms to generate multiple design options based on predefined constraints and goals, such as material usage or weight reduction. CAD software runs simulations to evaluate each design iteration, allowing designers to select and refine the best solution. This approach is particularly useful for innovative and optimized product development.

40. What is the role of sketching in CAD, and how do you ensure precision while sketching?

Sketching is the foundation of any CAD design, serving as the basis for creating 2D profiles and 3D models. To ensure precision, I use tools like snap-to-grid, constraints (e.g., perpendicularity and parallelism), and dimensioning. Regularly zooming in to align key points and validating the sketch against design specifications also ensures accuracy.

41. How do you manage design changes late in the development cycle?

Managing late design changes involves leveraging CAD tools like parametric modeling, which allows for quick adjustments without disrupting the overall design. I document all changes for traceability and communicate with stakeholders to understand the full impact. Using version control systems ensures that all revisions are properly tracked.

42. What are some common challenges in creating assemblies, and how do you address them?

Common challenges include part misalignment, interference between components, and maintaining clearances. I address these by:

- Running interference checks regularly.

- Using mates and constraints for precise alignment.

- Validating clearances with assembly simulations.

- Breaking assemblies into smaller sub-assemblies for easier management.

43. How do you ensure that a CAD design is optimized for cost-efficiency?

Cost-efficiency in CAD design is achieved by selecting materials that balance performance and price, simplifying geometries to reduce machining complexity, and minimizing waste. I use simulations to test different design options and collaborate with manufacturing teams to ensure the design is feasible and economical.

44. What is the significance of Bill of Materials (BOM) in CAD, and how do you generate it?

A BOM is a detailed list of all components, materials, and quantities required for a project. It is essential for manufacturing and procurement. In CAD software, I generate a BOM automatically by assigning attributes to components and organizing them hierarchically. I ensure that all data is accurate and updated to avoid errors during production.

45. What is topology optimization, and how is it applied in CAD?

Topology optimization is a design process that removes unnecessary material from a structure while maintaining its strength and functionality. In CAD, this is achieved using simulation tools that identify stress points and suggest material distribution. It is commonly applied in lightweight designs, particularly in automotive and aerospace industries.

46. How do you prepare CAD files for client presentations?

To prepare CAD files for client presentations, I create photorealistic renderings or animations using CAD’s visualization tools. I organize designs with clear annotations, dimensions, and exploded views to enhance understanding. Additionally, I export files in accessible formats like PDFs or video clips to ensure compatibility with the client’s systems.

47. What steps do you take to ensure your CAD models are compatible with CNC machines?

Ensuring compatibility involves:

- Using CAD/CAM-integrated software to streamline the transition.

- Exporting files in CNC-friendly formats like STEP or IGES.

- Verifying dimensions, tolerances, and tool paths.

- Simulating machining processes to identify potential issues.

- Consulting with machinists to align the design with their requirements.

Also Read: What is Computer – Aided Manufacturing?

48. What is the importance of feature-based modeling in CAD?

Feature-based modeling involves creating designs by combining features like extrusions, cuts, and fillets. This approach improves design clarity, as each feature is defined and editable. It also supports parametric design, making it easier to modify individual features without affecting unrelated parts of the model.

49. How do you handle confidentiality and security of CAD designs?

I handle confidentiality by storing files on secure servers and using access controls to restrict unauthorized editing. Encrypting files during transfer and maintaining backups in secure locations also ensure data integrity. Additionally, I follow company protocols for non-disclosure agreements and sensitive data handling.

50. What is the role of constraints in maintaining design integrity in CAD?

Constraints in CAD define relationships between geometric elements, ensuring the design maintains its intended shape and behavior even when changes are made. For instance, constraints like parallelism or concentricity enforce specific alignments, while dimensional constraints specify exact measurements. By applying constraints, I ensure that any modifications to one part of the design automatically update related elements without breaking the overall structure.

51. How do you use exploded views in CAD projects?

Exploded views visually separate the components of an assembly to show their relative positions and how they fit together. I use them to create instructional diagrams for assembly processes or maintenance guides. Exploded views are also helpful in identifying potential interferences or alignment issues during the design phase.

52. What are some common CAD modeling techniques for creating complex curves or surfaces?

Creating complex curves or surfaces often involves:

- Sweeping: Extending a profile along a path to create a surface.

- Lofting: Connecting multiple profiles to form a smooth transition between them.

- Blending: Smoothing the transition between intersecting surfaces.

- Splines: Using flexible curves to define intricate shapes.

- Boolean Operations: Combining solids to create unique forms.

53. How do you incorporate motion analysis into CAD designs?

Motion analysis involves simulating the movement of mechanical assemblies to ensure functionality. I use CAD tools to define joints, constraints, and motion paths for components. Simulations help identify interferences, optimize mechanisms, and validate design performance under dynamic conditions, such as rotational or linear motion.

54. What is a sectional view, and why is it important in CAD drawings?

A sectional view cuts through an object to reveal its internal features, providing a clearer understanding of complex designs. It is essential for showing hidden details, such as internal components or structures, that cannot be seen in standard views. I use sectional views to ensure manufacturing teams and stakeholders fully understand the design.

55. How do you create standardized templates in CAD software?

Creating standardized templates involves defining pre-set attributes such as layers, dimensions, text styles, and title blocks. I save these templates in formats compatible with the CAD software, ensuring consistency across projects. Templates streamline workflows by eliminating the need to set up these attributes for each new design.

56. How do you ensure that your CAD designs are accessible to non-technical stakeholders?

To ensure accessibility, I simplify CAD models by creating 3D renderings, animations, or 2D schematics with annotations and clear labels. Exporting files to user-friendly formats like PDFs or interactive 3D viewers allows non-technical stakeholders to review designs without needing CAD software expertise.

57. What is the difference between additive and subtractive manufacturing in CAD, and how does CAD facilitate both?

Additive manufacturing builds objects layer by layer, as in 3D printing, while subtractive manufacturing removes material from a solid block, as in CNC machining. CAD facilitates both by allowing designers to create precise 3D models, export them in formats like STL for additive processes, or generate machining instructions for subtractive techniques.

58. What is design intent, and how do you maintain it in CAD projects?

Design intent refers to the purpose behind a design, ensuring that it functions as intended even when changes are made. I maintain design intent by using parametric modeling, applying constraints, and organizing features logically. This ensures the design remains consistent and aligned with project goals throughout revisions.

59. How do you use CAD tools to estimate material usage and costs?

CAD software can estimate material usage by calculating volumes, surface areas, and weights of components. I use these features alongside built-in cost estimation tools or external calculators to provide accurate projections. Additionally, I simulate different material options to balance cost-efficiency with performance.

60. What are dynamic blocks in AutoCAD, and how do you use them?

Dynamic blocks in AutoCAD allow users to create a single block with multiple configurations, reducing the need for multiple static blocks. For example, a door block can include options for different sizes or swing directions. I use dynamic blocks to simplify designs, save time, and maintain consistency in drawings.

61. How do you approach designing for modularity in CAD projects?

Modularity in CAD projects involves creating designs that consist of interchangeable parts or modules. I ensure modularity by defining clear interfaces between components, using standardized dimensions, and designing for easy assembly and disassembly. This approach enhances flexibility and scalability in manufacturing.

62. What are the benefits of using feature trees in CAD software, and how do you utilize them?

Feature trees display the hierarchy and relationships of design features, enabling users to manage and edit complex models efficiently. I use feature trees to:

- Identify dependencies between features.

- Quickly navigate to specific elements for modification.

- Maintain a clear overview of the design structure.

- Roll back or suppress features to test alternative designs.

63. How do you use CAD to ensure proper clearances and tolerances in mechanical designs?

I use tools like interference detection and clearance analysis to verify that components fit together without overlapping. By defining tolerances during the design phase, I ensure that variations in manufacturing do not compromise the assembly’s functionality or safety.

64. How do you create a 3D model in AutoCAD?

Creating a 3D model in AutoCAD involves:

- Switching to a 3D workspace.

- Creating 2D profiles using drawing tools.

- Using commands like Extrude, Revolve, Sweep, and Loft to add depth or form.

- Applying materials and lighting for visualization.

- Validating the design with tools like 3D Orbit to inspect the model from all angles.

65. What is the difference between raster and vector graphics in CAD?

Raster graphics are pixel-based images (e.g., bitmaps or scanned drawings), while vector graphics are based on mathematical equations representing lines, curves, and shapes. CAD primarily uses vector graphics, as they are scalable and maintain precision, essential for technical drawings and designs.

66. What is the purpose of XREF (External References) in AutoCAD, and how do you manage them?

XREFs in AutoCAD allow users to reference external drawing files within a current drawing. This is particularly useful for collaborative projects, enabling multiple designers to work on different parts simultaneously. I manage XREFs by keeping file paths organized, ensuring they are up to date, and resolving any broken links promptly.

67. How do you implement design reuse in CAD projects?

Design reuse involves repurposing existing models or components to save time and effort. I implement design reuse by maintaining a library of standard parts, using templates for recurring projects, and modifying existing designs to meet new requirements. This approach ensures consistency and reduces development time.

68. What are some methods for enhancing CAD design visualization?

Some of the methods that can help improve visualization include:

- Using rendering tools to apply materials, textures, and lighting.

- Creating exploded views to show component relationships.

- Generating animations to simulate motion or assembly processes.

- Using augmented reality (AR) tools for immersive 3D visualization.

- Exporting designs into formats suitable for presentations, like PDFs or videos.

69. How do you ensure scalability in CAD designs for future updates or expansions?

Scalability is achieved by using parametric modeling, organizing components into modular structures, and maintaining detailed documentation. I anticipate potential future updates by designing flexible interfaces and leaving room for additional features. This ensures that the design can evolve without requiring a complete overhaul.

70. What is the importance of wireframe modeling in CAD, and when do you use it?

Wireframe modeling represents an object using lines and curves to define its edges, providing a basic 3D outline. It is useful in the early stages of design for visualizing and refining concepts. While wireframe models lack surface or volume details, they are lightweight and easy to modify, making them ideal for preliminary design iterations.

71. How do you use CAD software to create technical documentation?

CAD software allows for the creation of detailed technical documentation, including dimensioned drawings, exploded views, and material specifications. I use annotation tools, apply industry-standard symbols, and ensure that the documentation aligns with project requirements. Exporting in formats like PDF ensures accessibility for stakeholders.

72. How do you address interoperability issues between different CAD software?

Interoperability issues are addressed by using neutral file formats like STEP, IGES, or DXF for cross-platform compatibility. I also ensure proper import/export settings and validate designs after file conversion to detect any data loss or distortions. When necessary, I use third-party conversion tools to bridge software gaps.

73. How do you integrate CAD designs into BIM (Building Information Modeling) workflows?

Integrating CAD into BIM involves exporting CAD drawings into compatible formats like IFC or DWG. I ensure that all elements in the CAD file are properly structured and labeled for seamless import into BIM software. This integration helps in collaborative planning, as stakeholders can view CAD designs alongside 3D models and project data.

74. What strategies do you use for handling large assemblies in CAD software?

Handling large assemblies efficiently involves:

- Organizing components into sub-assemblies.

- Suppressing unused parts to reduce system load.

- Using lightweight representations for non-critical components.

- Running performance optimization tools provided by CAD software.

- Validating the design progressively to avoid major revisions later.

75. What is the purpose of dimensioning in CAD, and how do you apply it?

Dimensioning provides numerical values to indicate the size, distance, and angles of features in a design. I apply dimensioning using tools like linear, radial, and angular dimensions, ensuring they are positioned clearly without cluttering the drawing. Proper dimensioning ensures accurate manufacturing and assembly by providing clear specifications.

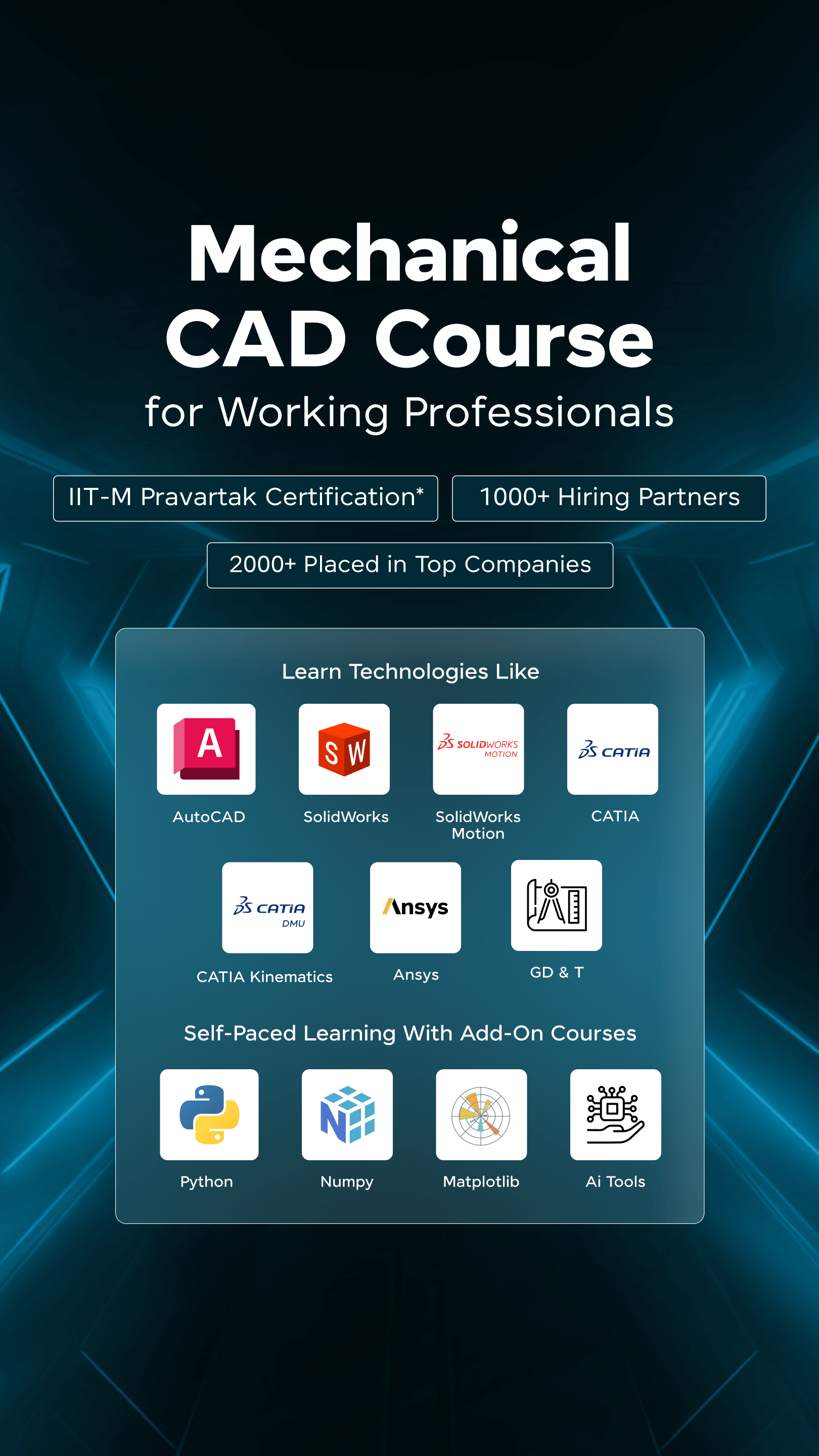

Kickstart your career by enrolling in CAD Design and Simulation Course for mechanical engineers where you’ll master technologies including AutoCAD, SolidWorks, CATIA, Ansys, GD & T etc., and build interesting real-life mechanical projects.

Alternatively, if you’d like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take up GUVI’s AutoCAD Mechanical Course .

Wrapping Up

We hope this guide to CAD interview questions and answers has provided you with the knowledge and confidence to excel in your next interview. By thoroughly preparing with these questions, you can upgrade your knowledge in CAD tools and concepts, while addressing real-world design challenges with confidence.

This resource will help you refine your answers, align with industry expectations, and stand out as a capable candidate. If you’re just beginning your journey or even have years of experience, mastering these CAD job interview questions will undoubtedly pave the way for a successful and rewarding career in the field.

Frequently Asked Questions

Common CAD job interview questions include topics like your experience with CAD software, understanding of 2D and 3D modeling, knowledge of parametric design, and examples of challenging design projects you’ve handled. Questions may also focus on industry-specific applications of CAD.

To prepare thoroughly, review the fundamentals of CAD software, practice commonly used commands, and create a portfolio showcasing your best work. Additionally, study common CAD job interview questions and be ready to discuss real-world examples of projects you’ve worked on.

Many CAD interviews include a practical assessment where candidates are asked to complete a design task or demonstrate their proficiency with software tools like AutoCAD or SolidWorks. Practicing with these tools beforehand can help you perform confidently during such evaluations.

Interviewers usually look for proficiency in CAD software, attention to detail, creativity in solving design problems, and the ability to collaborate with cross-functional teams. Strong communication skills and a clear understanding of industry standards are also highly valued.

![Top 40 Data Science Interview Questions for Freshers [2025] 3 data science interview questions for freshers](https://www.guvi.in/blog/wp-content/uploads/2025/06/Top-40-Data-Science-Interview-Questions-for-Freshers-2025.png)

Did you enjoy this article?